Soft Lithography

Anatech SCE 108 Barrel Asher

TOOL ID: DE-02

Anatech USA’s SCE-100 Series Inductively Coupled (ICP) Plasma systems are extremely effective for a Plasma Ashing process to activate a surface prior to bonding PDMS, e.g.

Process gases is O2. Sample sizes are pieces to 100mm round wafers.

Go to Page

ABM HTG 3000HR Mask Aligner

Tool ID: MA-03

Location: Bay 6

The ABM mask aligner is a manual and versatile mask aligner with top-side alignment and substrate capabilities from 100mm down to small pieces. This tool is used primarily for negative resist exposure and alignment of PDMS components for bonding. The flexible range of the microscope makes this tool also well utilized for top-side alignment of small pieces. The 350W Hg bulb provides an approximate 365nm output intensity of 20 mW/cm² and 400nm output intensity of 45 mW/cm², with ± 3-5% uniformity across a wafer.

Go to Page

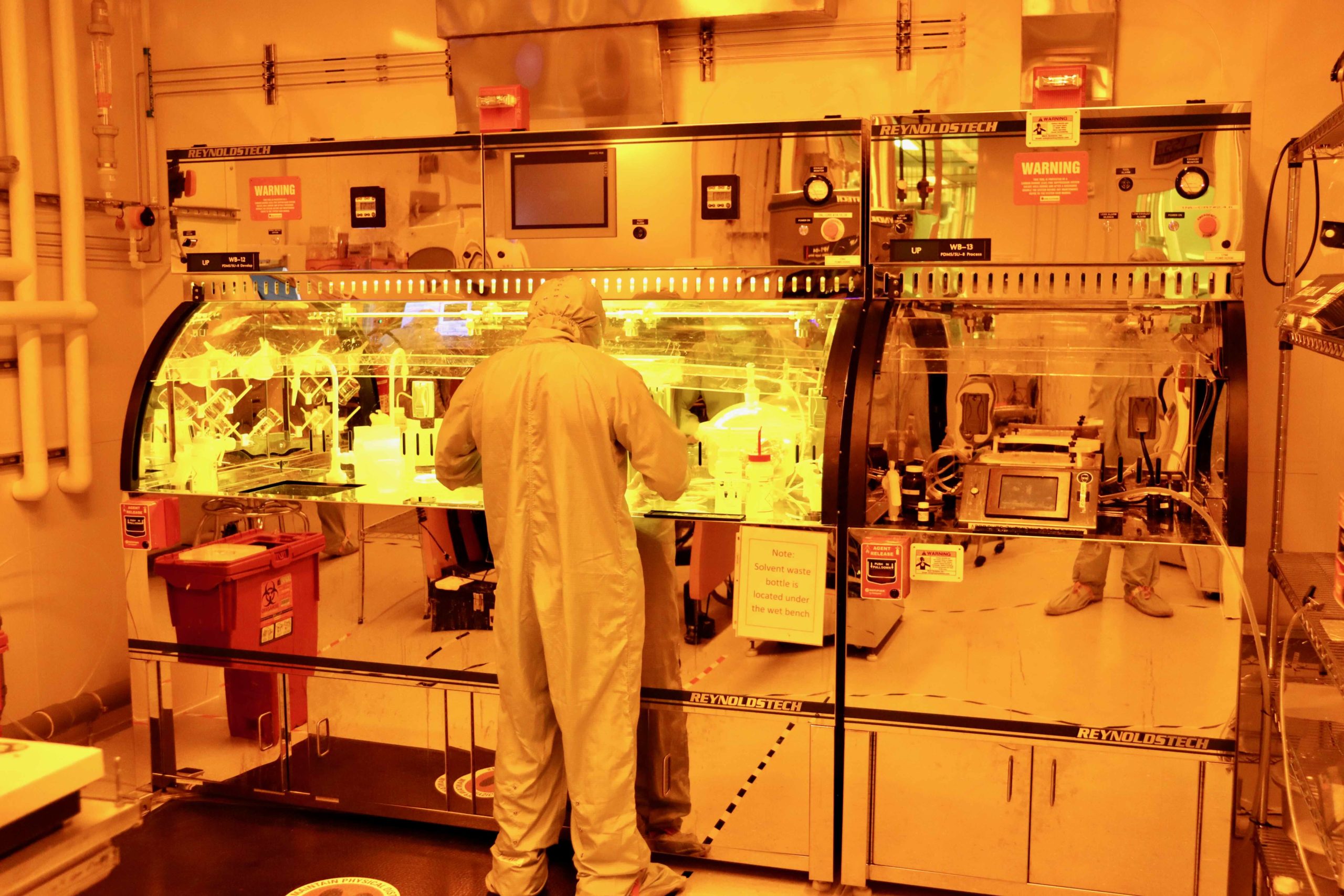

Spinner and Solvent Processing Benches

SU-8/PDMS Resist Spinner

TOOL ID: SPN-07

- Maximum speed of 10,000 rpm

- User friendly programmable interface

- Programmable step functions (up to 10 steps per recipe)

- Programmable process control

- Wafer sizes from pieces through 150mm

Vacuum Oven

Vacuum oven capable of reaching ~10 Torr with digital gravity convection for curing samples from 25-250C

Go to Page