Quattrone Nanofabrication

Cambridge NanoTech S200 ALD

TOOL ID: ALD-01

Savannah is equipped with high-speed pneumatic pulse valves to enable our unique Exposure Mode™ for thin film deposition on Ultra High Aspect Ratio substrates. This proven precision thin film coating methodology can be used to deposit conformal, uniform films on substrates with aspect ratios of greater than > 2000:1.

The Penn Savannah is capable of holding substrates of different sizes (up to 200mm). It is equipped with six precursor lines for deposition of Al2O3, HfO2, TiO2, and SiO2.Go to Page

Denton Vacuum Explorer 14 Sputterer

TOOL ID: PVD-05

- Open load system in sputter-down configuration

- Two DC guns

- Able to co-sputter one DC and one RF source

- One RF gun

- Cryo pumped with automated interface

- Automated control of film thickness

- Pieces through 150mm wafers

- Wafer platen rotation with cooling

- Substrate cleaning

Evatec Clusterline 200 II Sputter

TOOL ID: PVD-06

The system is owned and managed by the Olsson Group at UPenn. Inquiries into using the system should be made to staff via an email at qnf-process@lists.seas.upenn.edu .

The tool is configured to sputterer piezo-electric materials, including Al and Sc.Go to Page

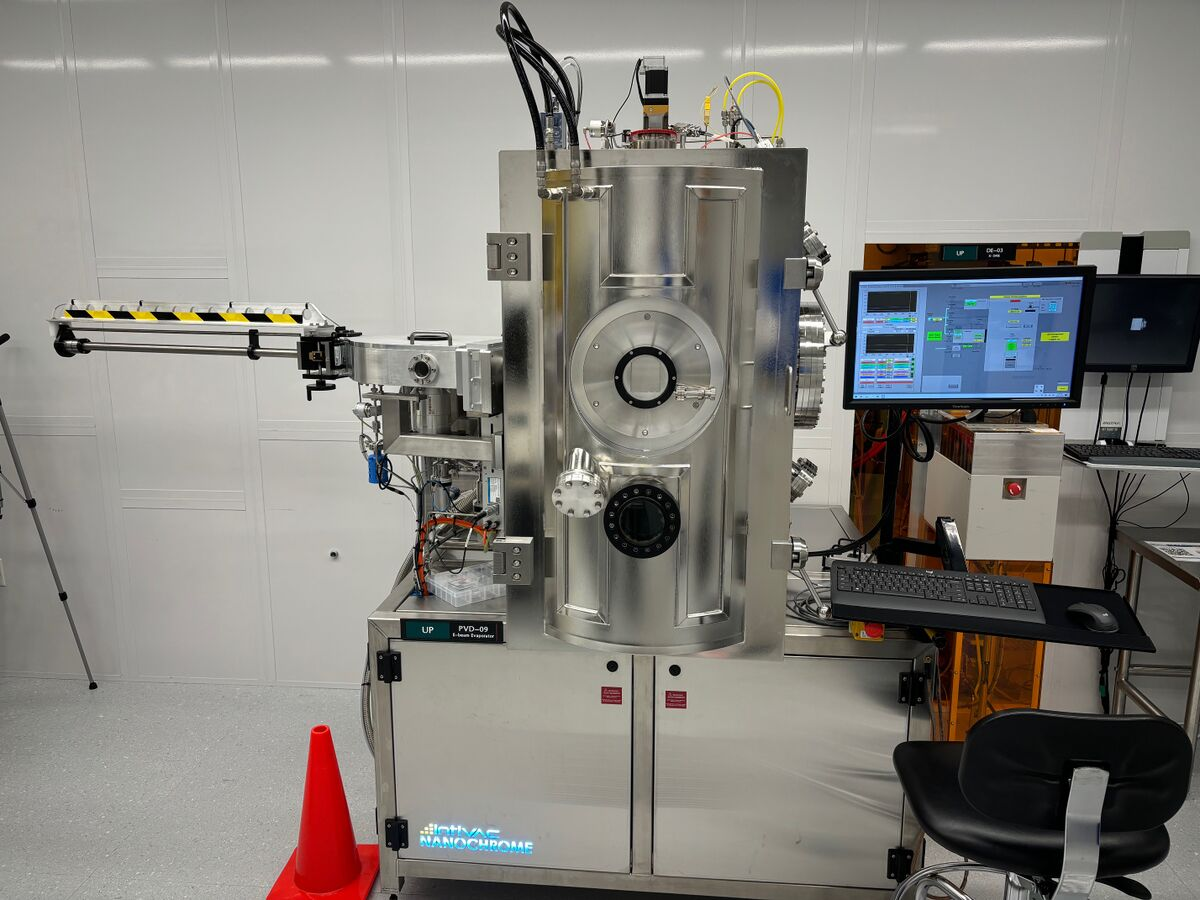

IntlVac Nanochrome Electron Beam Evaporator

IntlVac Nanochrome Electron Beam Evaporator

The IntlVac Nanochrome Electron Beam Evaporator has a base process chamber pressure in the low e-8 Torr range with substrate heating and ozone purging capabilities. Deposition rates are monitored by an automated magazine of 6MHz crystals. The tool can be used to process a single 4 inch wafer at a time or a selection of small chips/pieces.

Kurt J. Lesker PVD 75 – E-Beam/Thermal Evaporator

TOOL ID: PVD-02

- Two thermal sources

- Four pocket e-beam at 10kV

- Cryo pumped with automated interface

- Automated control of film thickness

- Pieces through 150mm wafers

- Wafer plate rotation with cooling stage

Kurt J. Lesker Nano 36 Thermal Evaporator

TOOL ID: PVD-01

- Three thermal sources

- Turbo pumping automated interface

- Automated control of film thickness

- Pieces through 150mm wafers

- Wafer platen rotation

Kurt J. Lesker PVD 75 PRO-Line Sputterer

TOOL ID: PVD-03

- Load locked system

- Three DC guns

- Able to co-sputter two DC sources

- One RF gun

- Cryo pumped with automated interface

- Automated control of film thickness

- Pieces through 150mm wafers

- Wafer platen rotation with heating

Oxford Instruments Plasma Lab 100 PECVD

TOOL ID: CVD-01

This is a load locked PECVD system capable of depositing SiO2, Si3N4 and a-Si. Process temperatures range from room temperature through 400C. In addition to standard RF plasma, there is a low frequency source for stress tuning films. The system handles 4”/100mm wafers.Go to Page

Sandvik LPCVD & Anneal Furnace

TOOL ID: CVD-02

The Sandvik LPCVD consists of 4 horizontal tubes:

Tube 1: Wet/Dry Silicon Oxide deposition.

Tube 2: Low Stress Silicon Nitride deposition.

Tube 3: Clean anneal.

Tube 4: General anneal.

The tool is configured for 100 mm (4″ wafers) and can process up to 50 wafers at a time.

Go to Page

SMI MOCVD

TOOL ID: CVD-04

The system is owned and managed by the Jariwala Group at UPenn. Inquiries into using the system should be made to staff via an email at qnf-process@lists.seas.upenn.edu .

The systems is a Metal-organic chemical vapor deposition system configured with the following precursors: (CH3)2Se, Mo(CO)6, (CH)3 In, H2, H2S.Go to Page

Ultratech Fiji G2 ALD

TOOL ID: ALD-02

Fiji is a plasma and thermal ALD equipped with high-speed pneumatic pulse valves to enable our unique Exposure Mode for thin film deposition on Ultra High Aspect Ratio substrates. This proven precision thin film coating methodology can be used to deposit conformal, uniform films on substrates with aspect ratios of greater than > 2000:1. Fiji is capable of holding substrates of different sizes up to 200mm. The Fiji thin film deposition system is equipped with TMA, DEZ, and water.

Veeco Savannah S200 ALD

TOOL ID: ALD-03

Savannah is equipped with high-speed pneumatic pulse valves to enable our unique Exposure Mode for thin film deposition on Ultra High Aspect Ratio substrates. This proven precision thin film coating methodology can be used to deposit conformal, uniform films on substrates with aspect ratios of greater than > 2000:1. Savannah is capable of holding substrates of different sizes up to 200mm. The Savannah thin film deposition systems are equipped with heated precursors lines and the option to add up to six lines.Go to Page

Anatech SCE 108 Barrel Asher

TOOL ID: DE-02

Anatech USA’s SCE-100 Series Inductively Coupled (ICP) Plasma systems are extremely effective for a Plasma Ashing process to activate a surface prior to bonding PDMS, e.g.

Process gases is O2. Sample sizes are pieces to 100mm round wafers.Go to Page

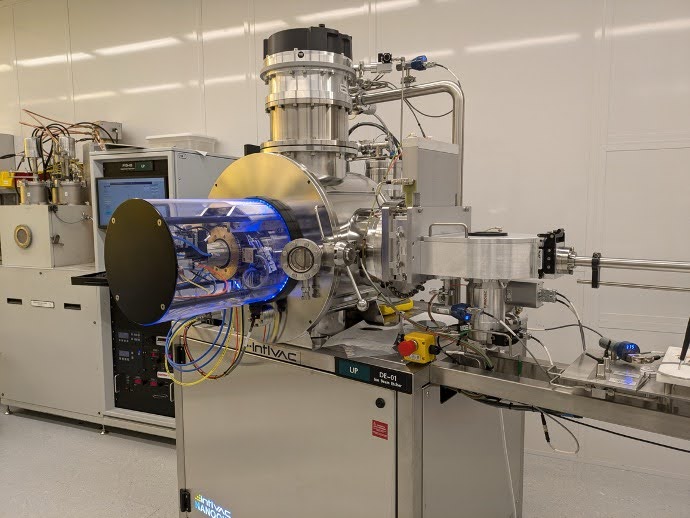

IntlVac NanoQuest 1 IBE

IntlVac NanoQuest 1 IBE

NanoQuest 1 is an ion mill connected to Ar gas and capable of etching small mm-scale samples up to full 4″ wafers. The tool is equipped with a secondary ion mass spectroscopy (SIMS) unit and is capable of etch with manual endpoint detection. The stage has a tilt motor that allows for etch angles between 0 (directly facing the beam) and 90 degrees (parallel to the beam).

The tool in QNF is connected to Ar gas and can etch samples up to 4″ wafer. Available beam voltages are: 300 V, 400 V, 450 V, and 500 V

March Jupiter II Etcher

TOOL ID: DE-08

The March Jupiter II is a reactive ion etcher configured with O2 gas. The system is typically used as a plasma asher/cleaner.

Oxford Instruments Plasma Lab 80+ RIE

TOOL ID: DE-04

A compact open-loading tool for Reactive Ion Etching – Oxford 80+ RIE

The Oxford 80+ offers versatile reactive ion etch solutions on one platform with convenient open loading. This compact, small footprint system is easy to use, with no compromise on process quality.

It is ideally suited to R&D or small-scale production, and can process from the smallest wafer pieces to 200mm wafers. The open load design allows fast wafer loading and unloading, ideal for research, prototyping and low-volume production.

- 600W RF generator

- Up to 200mm wafers

- Process gases: CF4, Ar, O2, SF6 and CHF3

- Excellent etch control

- Excellent process control

- Documented baseline recipes are provided by Penn’s QNF staff

Oxford PlasmaPro 100 Cobra ICP

TOOL ID: DE-5

The PlasmaPro 100 Cobra ICP RIE system utilizes a high-density inductively coupled plasma to achieve fast etch rates. The process modules offer excellent uniformity, high-throughput, high-precision and low-damage processes for wafer sizes up to 4″ or 100mm.

The tool is connected to the following gases: BCl3, Cl2, Ar, O2, SF6, CF4, and CHF3.

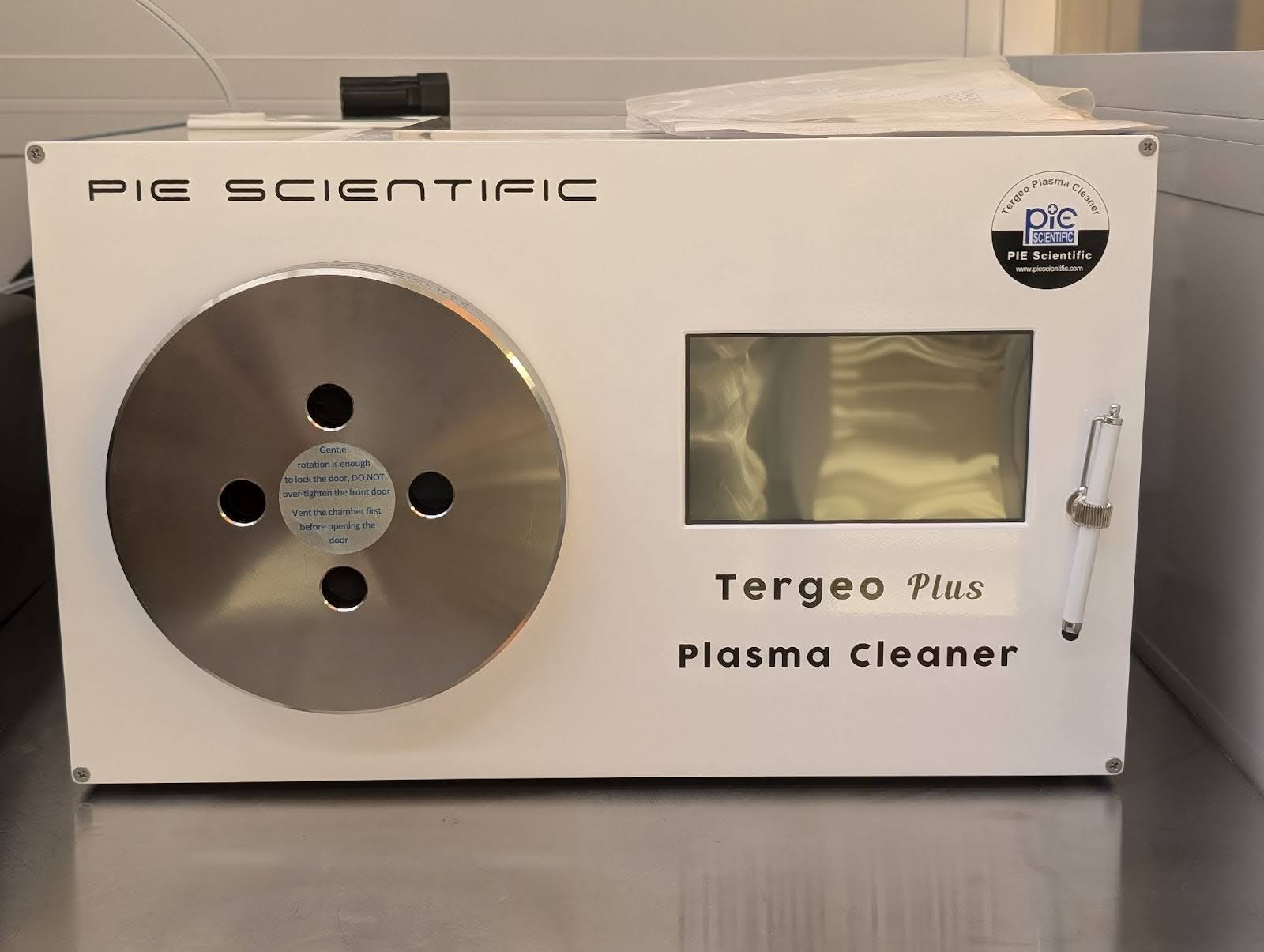

DE-09: PIE Scientific Tergeo-Plus

DE-09: PIE Scientific Tergeo-Plus

The PIE Scientific Tergeo-Plus Plasma Cleaner is an RF etcher designed for sample cleaning and ashing of resist with a maximum power of 500 W. It is equipped with three process gasses, O2, Ar, and H2O. It is capable of direct or downstream plasma, pulsed plasma mode, and has in-situ plasma monitoring for precise process control. The tool can hold samples from piece parts to a single 6” wafer. It can also hold a cassette of 25 4” wafers.

SPTS Rapier Si DRIE

TOOL ID: DE-03

With an installed base of over 1000 DRIE process modules, SPTS’ market-leading position is spearheaded by the Rapier module, which etches Si using Bosch switched processing as well as non-switched etching for tapered profiles, wafer thinning and via reveal.

Advantages of SPTS Si DRIE

- Patented dual plasma source design with independently controlled primary and secondary decoupled plasma zones, with independent dual gas inlets. This results in a highly concentrated and uniformed distribution of radicals.

- High etch rate

- Excellent uniformity

- Controls tilting of deep features across the wafer

- Inherent multi-mode flexibility also allows complementary oxide etching within the same hardware.

Delivering unparalleled process capability with world-class productivity & cost of ownership benefits, SPTS’ DRIE process modules are used in a wide variety of applications across multiple end markets.Go to Page

Xactix e1 XeF2 Etch System

TOOL ID: DE-6

Isotropic etching of silicon using xenon difluoride is an ideal solution for releasing MEMS devices. XeF2 shows high selectivity to silicon over almost all standard semiconductor materials including photoresist, silicon dioxide, silicon nitride and aluminum. Being a vapor phase etchant, XeF2 avoids many of the problems typically associated with wet or plasma etch processes.

Built for simplicity, and a small footprint, the Xactix® e1TM is the ideal solution for requiring an R&D xenon difluoride etching system. This table top etcher is ideal for small volumes in QNF.

Key Benefits

- Simple & reliable

- Great for working with small samples and wafers

Beamer and Tracer Lithography Software

TOOL ID: EBL-02

The Quattrone Nanofabrication Facility (QNF) features state-of-the-art software for next-generation electron beam (e-beam), mask aligner and laser lithography. Specifically, the software package, BEAMER and TRACER, offers advanced data preparation, 2D and 3D proximity effect correction (PEC), process modeling and simulation for direct write applications in e-beam and laser lithography.Go to Page

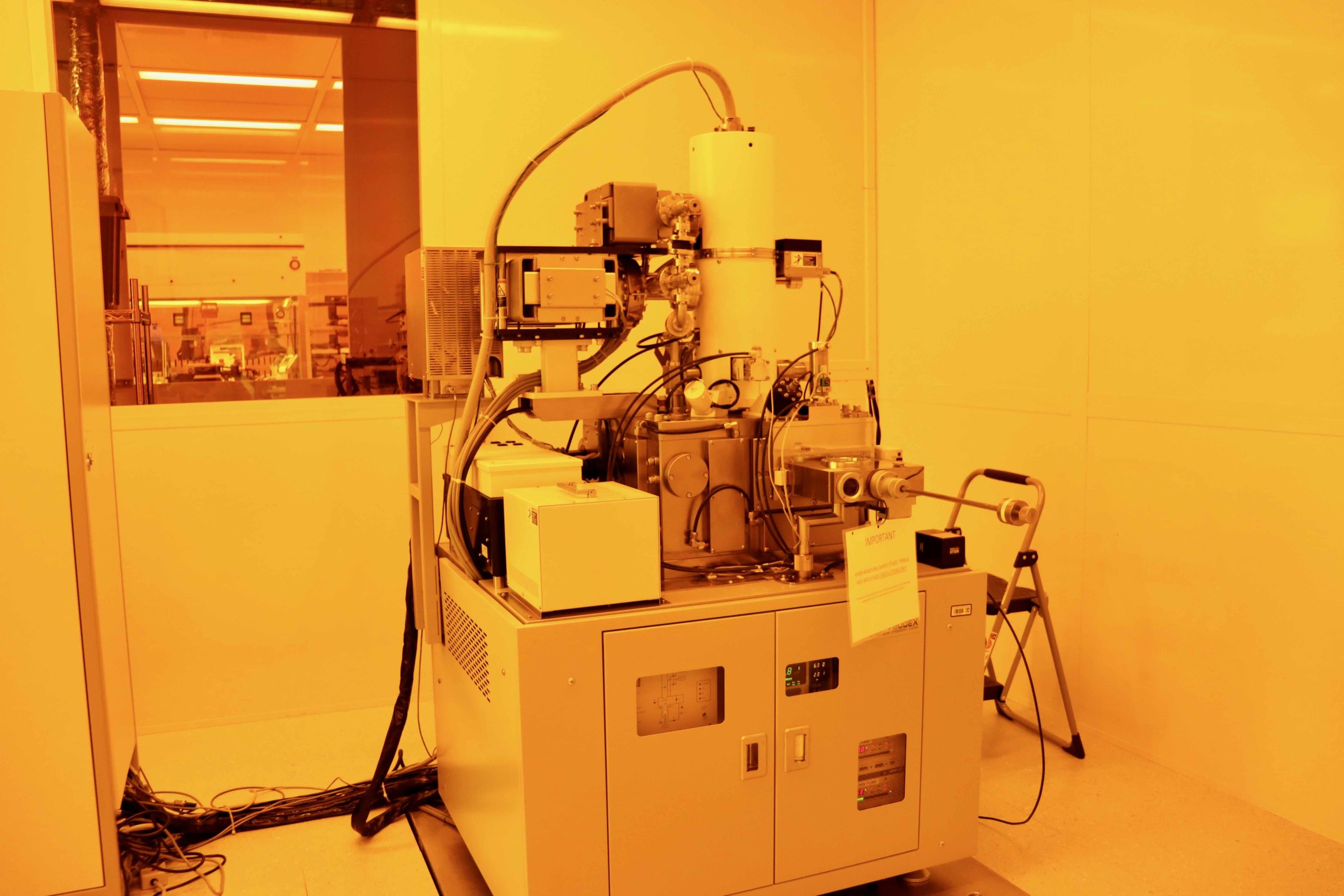

Elionix ELS-7500EX EBL

TOOL ID: EBL-01

Ultra-high precision lithography with a resolution of 10 nm and with high stitching and overlay accuracy.

Specifications

| Electron gun emitter | ZrO/W thermal field emitter |

| Acceleration voltage | 50kV,30kV,20kV |

| Minimum line width | 10nm |

| Specimen size | 6″ (maximum) |

Features

Ultra-fine lithography.

- The 2-nm diameter spot beam allows the ultra fine pattern writing of 10 nm width. ELS-7500EX incorporates SEM function that serves for exposed pattern observation.

High stitching and overlay accuracy.

- ELS-7500EX provides overlay accuracy of 30 nm that supports mix-and-match with photolithography.

- The recipe function, with saved optimum beam settings, provides the ease of the operation.

- The stage with a built-in laser interferometer and beam positioning resolution of 0.31 nm with an 18-bit DAC provide a stitching accuracy of 30 nm.

High performance with compact configuration. Ease of operation with PC control.

- Integration of a Windows compatible GUI and CAD realizes a small footprint.

- Electron optical condition control and CAD pattern design can be accomplished by simply using a mouse. A very user friendly system.

Application gallery

R = 100μm blazed circle

(Pitch in the radius direction 1.0μm)

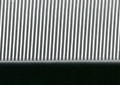

L&S: 80 nm

Resist Thickness: 1.5μm || Line width: 25 nmGo to Page

Genesis HMDS Vapor Prime Oven

TOOL ID: OVN-01

While wet chemical surface modification can be done, vapor phase deposition has become the preferred method for coating surface as the process environment can be tightly controlled. Due to liquid surface tension, the wet process can have poor contact between the solution and the surface, especially when the surface is textured with small features. Another problem with wet processing, or solution phase deposition, is this process typically uses water.

Standard recipes include HMDS priming and image reversal with ammonia chemistry. Other chemistry and related SAM coatings can be developed on request.Go to Page

Heidelberg DWL 66+ Laser Writer

Tool ID: LW-01

Location: Bay 4

The DWL 66+ laser writing system can be used for the patterning of photomasks, iterative testing of patterns as well as direct writing for small or temporary use cases. Global and feature alignment is available for direct write layers, using both top-side and bottom-side cameras. The laser is 405nm wavelength (h-line).

Lens & Resolution

- 2 mm lens : 600 nm

- 10 mm lens: 2 µm

Applications

- Patterning of photomasks

- Direct laser writing on substrates, from 6″ wafers down to 10mm x 10mm pieces

Allowed Materials

- Mask Plates — available in the QNF Stockroom pre-coated with AZ1500 and IP3500

- Resists — must be compatible with h-line exposure. Includes S1800 series, KL5300 series, LOR

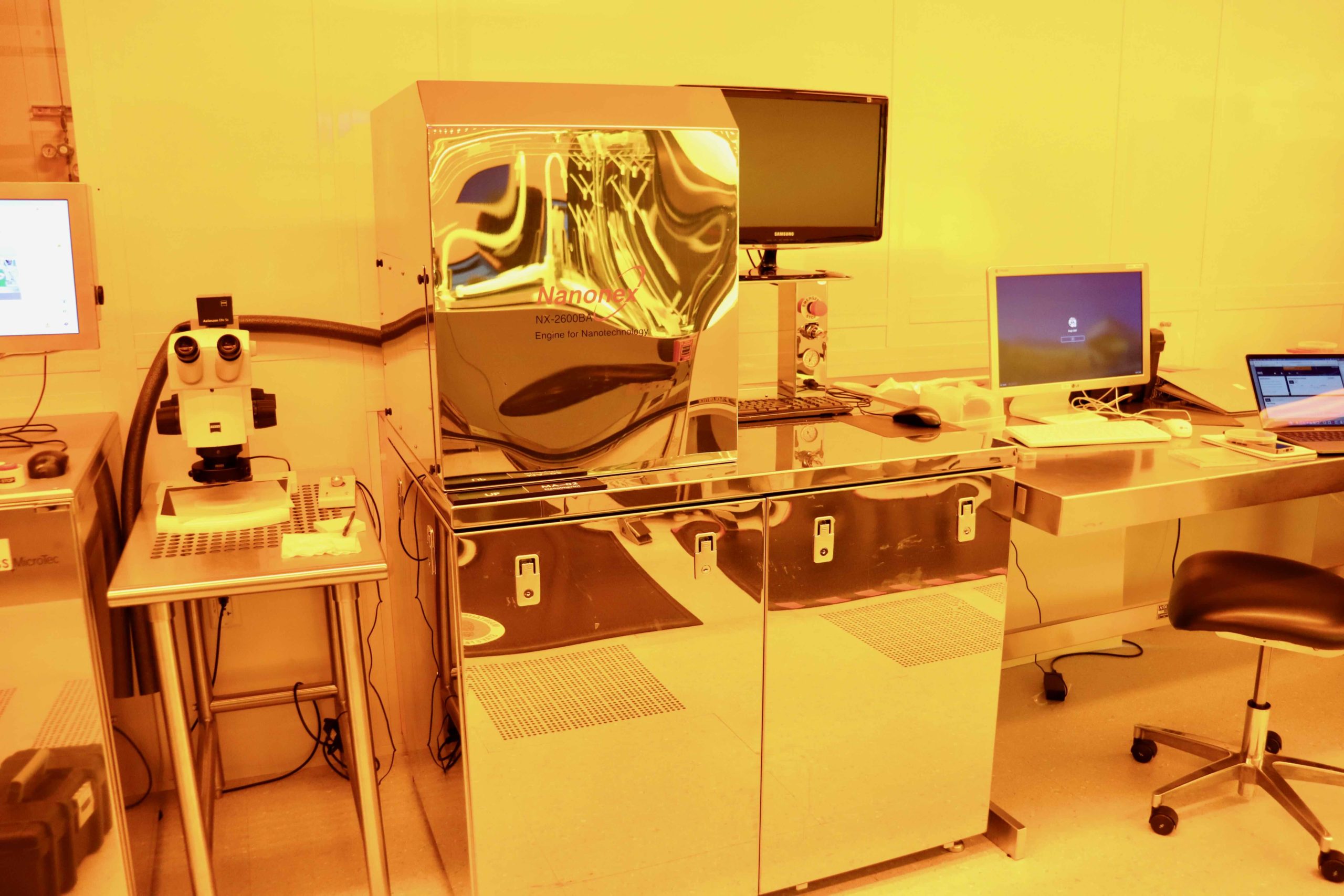

Nanonex 2600 Nanoimprinter

TOOL ID: MA-02

The Nanonex NX-2600 is a full wafer nanoimprinter. It is capable of all imprint forms: thermal, photo-curable, and embossing, with sub-5nm imprinting resolution and sub-1 micrometer alignment accuracy. Based on the Nanonex unique patented Air Cushion PressTM technology, the NX-2600 offers unsurpassed uniformity regardless of backside topology, wafer or mask flatness, or backside contamination. This ACP technology also eliminates lateral shifting between the mask and substrate, which significantly increases mask lifetime.

Standard nanoimprint resists are provided.Go to Page

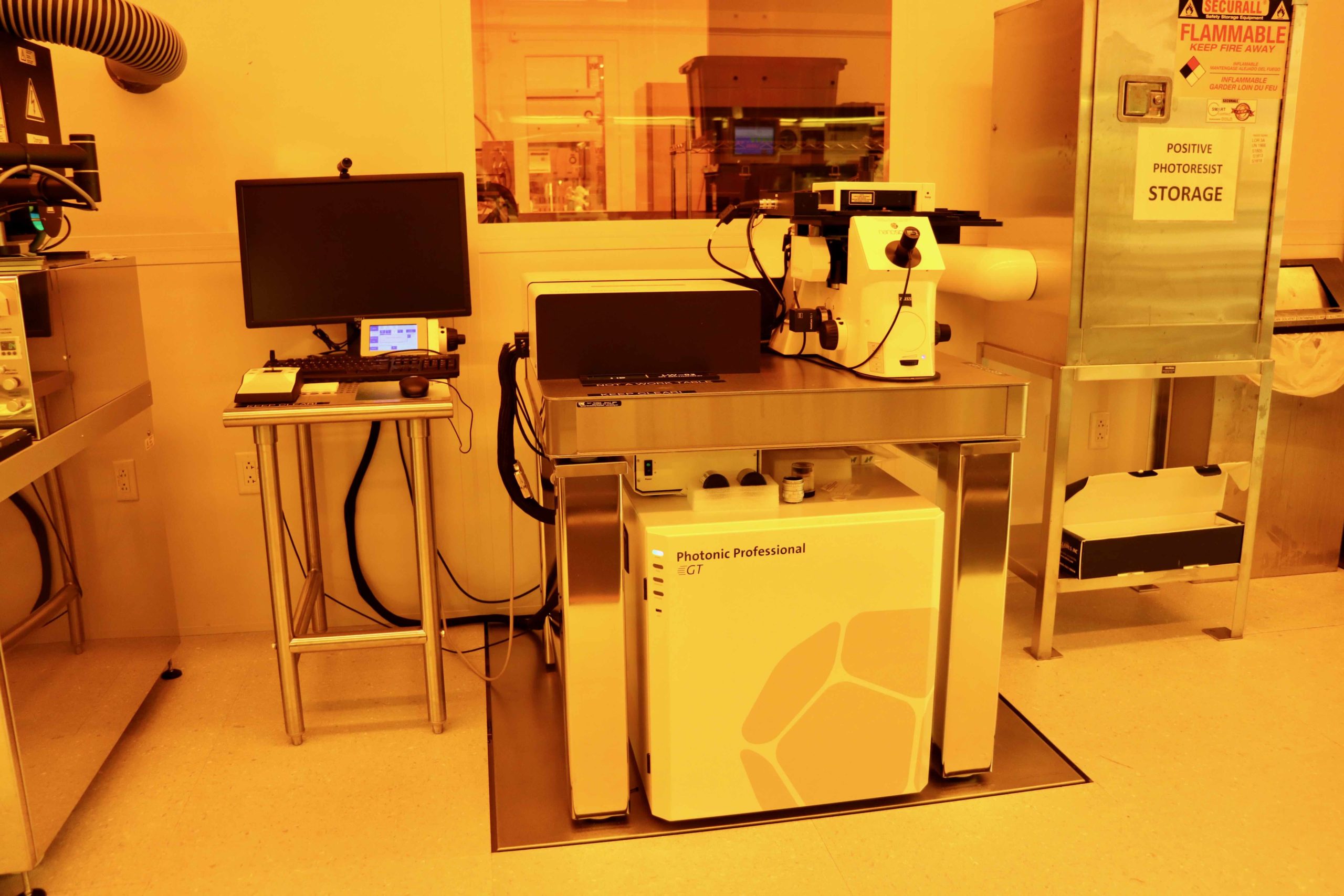

Nanoscribe Photonic Professioal GT

TOOL ID: LW-02

The NanoScribe Photonic Professional GT, a nano-micro 3D laser printer for a variety of research applications. The tool has been demonstrated to enhance life science research in the areas of cell/extracellular matrix interaction, targeted drug delivery, cell migration, tissue engineering and 3D cell culture. The tool’s ease of use shortens the learning curve and will enable a new era of research for our users. Using two photon polymerization, the tool is capable of writing using the ultra-precise piezo stage or high speed galvanometer. Go to Page

Ovens and Hotplate Towers

Each hot plate tower in QNF is outfitted with digital thermal hot plates that can be heated to 350C with controlled ramping. In addition, there are stainless steel gravity convection ovens capable of heating to 300C in each tower as well. Several baking stations are located throughout the QNF, each dedicated to specific resist process and polymer curing.Go to Page

The Raith EBPG5200+ is an electron beam lithography tool capable of high-resolution patterning at 100 kV. It has a 125 MHz pattern generator, a maximum current of 350 nA, and a 1 mm mainfield size. It has an automatic aperture changer, automatic and dynamic focus and stigmation, and automatic alignment. The EBPG can achieve linewidths <8nm with stitching and overlay accuracy better than 10nm.

The Raith EBPG5200+ is an electron beam lithography tool capable of high-resolution patterning at 100 kV. It has a 125 MHz pattern generator, a maximum current of 350 nA, and a 1 mm mainfield size. It has an automatic aperture changer, automatic and dynamic focus and stigmation, and automatic alignment. The EBPG can achieve linewidths <8nm with stitching and overlay accuracy better than 10nm.

Applications

- Large-scale, high-speed patterning of positive and negative e-beam resists with features from <10 nm to micron/mm scale

Allowed Materials

- Standard semiconductor materials

- Low vapor pressure metals

- Resists

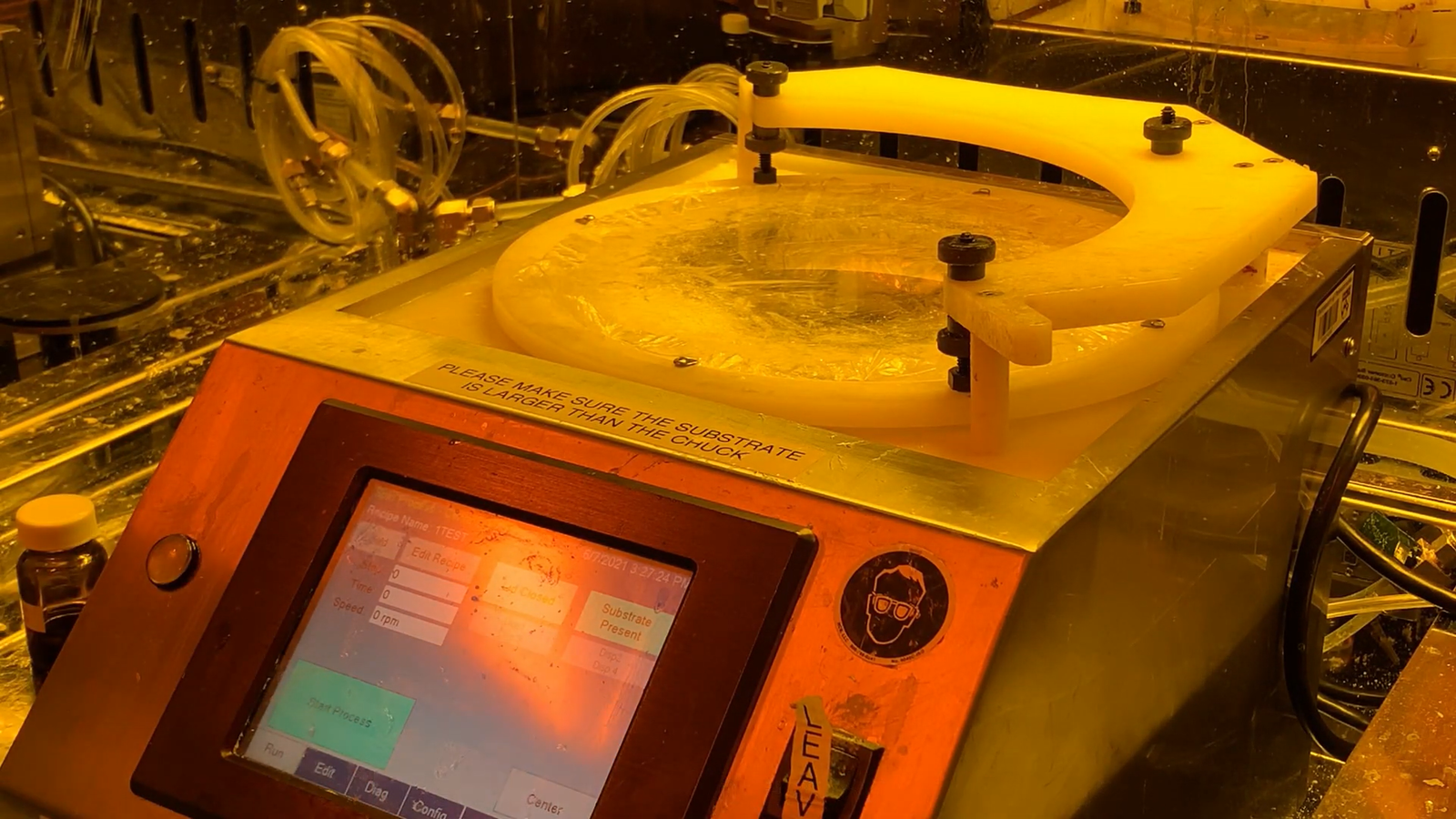

Resist and Polymer Spinners

The QNF maintains several resist and polymer spinners throughout the cleanroom. Each spinner is dedicated to specific resist and polymer types to reduce cross contamination.

- Maximum speed of 10,000 rpm

- User friendly programmable interface

- Programmable step functions (up to 10 steps per recipe)

- Programmable process control

- Wafer sizes from pieces through 150mm

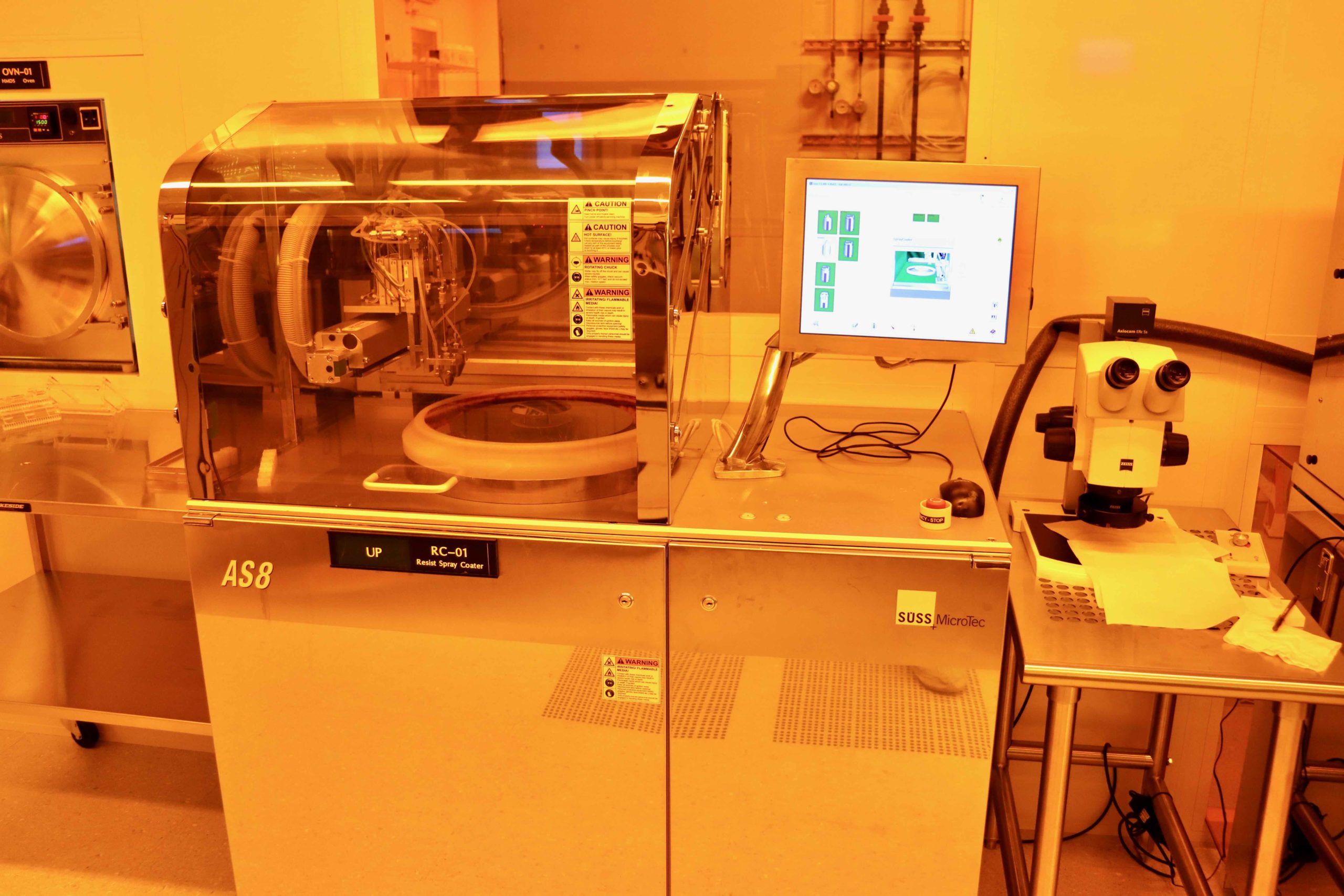

SUSS MicroTec AS8 AltaSpray Coater

TOOL ID: RC-01

Automated Spray Coater for High Topographies

SUSS MicroTec’s proprietary AltaSpray coating technology is a unique resist deposition method that is capable of producing highly uniform resist films on different 3-D microstructures. The AltaSpray technology is capable of coating 90° corners, KOH etched cavities, Through Silicon Vias (TSVs) or lenses with topographies ranging from a few micron to 600µm or more. The ability to produce conformal resist coatings on severe topography makes them the ideal choice for R&D, MEMS, 3D-Integration and Wafer Level Packaging applications like 3D image sensor packaging.

Wafer sizes from pieces to 200mm. Common resists sprayed are SU-8, S1800 and various AZ formulations.

SUSS Microtec MA6 Gen3 Mask Aligner

SUSS Microtec MA6 Gen3 Mask Aligner

Tool ID: MA-01

Location: Bay 5

The SUSS MA6 Mask Aligner is set up for piece parts to 6″ wafers, with first mask, top-side alignment, bottom-side alignment, and flood exposure. Mask alignment is possible for both contact and proximity exposure processes. Exposures can be performed with gaps programmable from 10 um to 300 um in 1 um increments. Automatic wedge error compensation (WEC) is used to ensure that the mask and wafer are parallel. The lamp is a 1000 W Hg-Arc lamp. Integrated light level sensing ensures proper exposure doses in both 365nm and 405nm, even as the lamp degrades. For some applications it can be beneficial to eliminate wavelengths below 365nm using an installable long pass filter.

Applications

* First mask exposure of resist-coated samples for patterning

* Aligned mask exposure of resist-coated samples for patterning

* Flood exposure of resist-coated samples for image reversal

* Flood exposure of samples for further cross-linking of resist/resin

Anatech SCE 106 Barrel Asher

TOOL ID: DE-07

Anatech USA’s SCE-100 Series Inductively Coupled (ICP) Plasma systems are extremely effective for a Plasma Ashing process to remove organics prior to thin film deposition and/or chemical analysis of remaining inorganics.

Process gases are CF4, O2, Ar and N2. Sample sizes are pieces to 150mm round wafers.Go to Page

ABM HTG 3000HR Mask Aligner

ABM HTG 3000HR Mask Aligner

Tool ID: MA-03

Location: Bay 6

The ABM mask aligner is a manual and versatile mask aligner with top-side alignment and substrate capabilities from 100mm down to small pieces. This tool is used primarily for negative resist exposure and alignment of PDMS components for bonding. The flexible range of the microscope makes this tool also well utilized for top-side alignment of small pieces. The 350W Hg bulb provides an approximate 365nm output intensity of 20 mW/cm² and 400nm output intensity of 45 mW/cm², with ± 3-5% uniformity across a wafer.

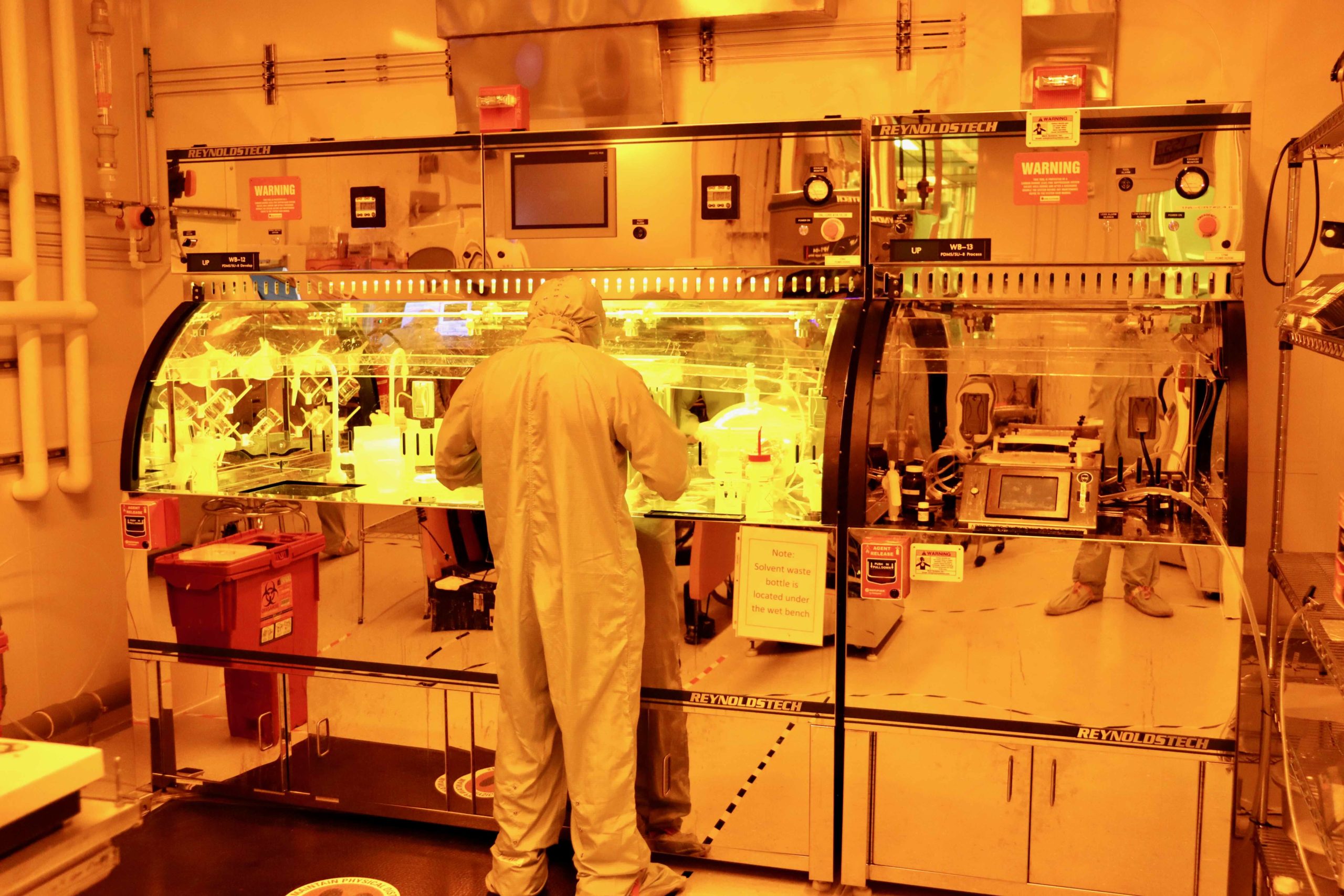

Spinner and Solvent Processing Benches

SU-8/PDMS Resist Spinner

TOOL ID: SPN-07

- Maximum speed of 10,000 rpm

- User friendly programmable interface

- Programmable step functions (up to 10 steps per recipe)

- Programmable process control

- Wafer sizes from pieces through 150mm

Filmetrics F40 Reflectometer

TOOL ID: MET-04

The F40 has an integrated color video camera that allows exact monitoring of the film thickness measurement spot. Thickness and index can be measured in less than a second. The F40 product family is for applications that require a spot size as small as 1 micron.Go to Page

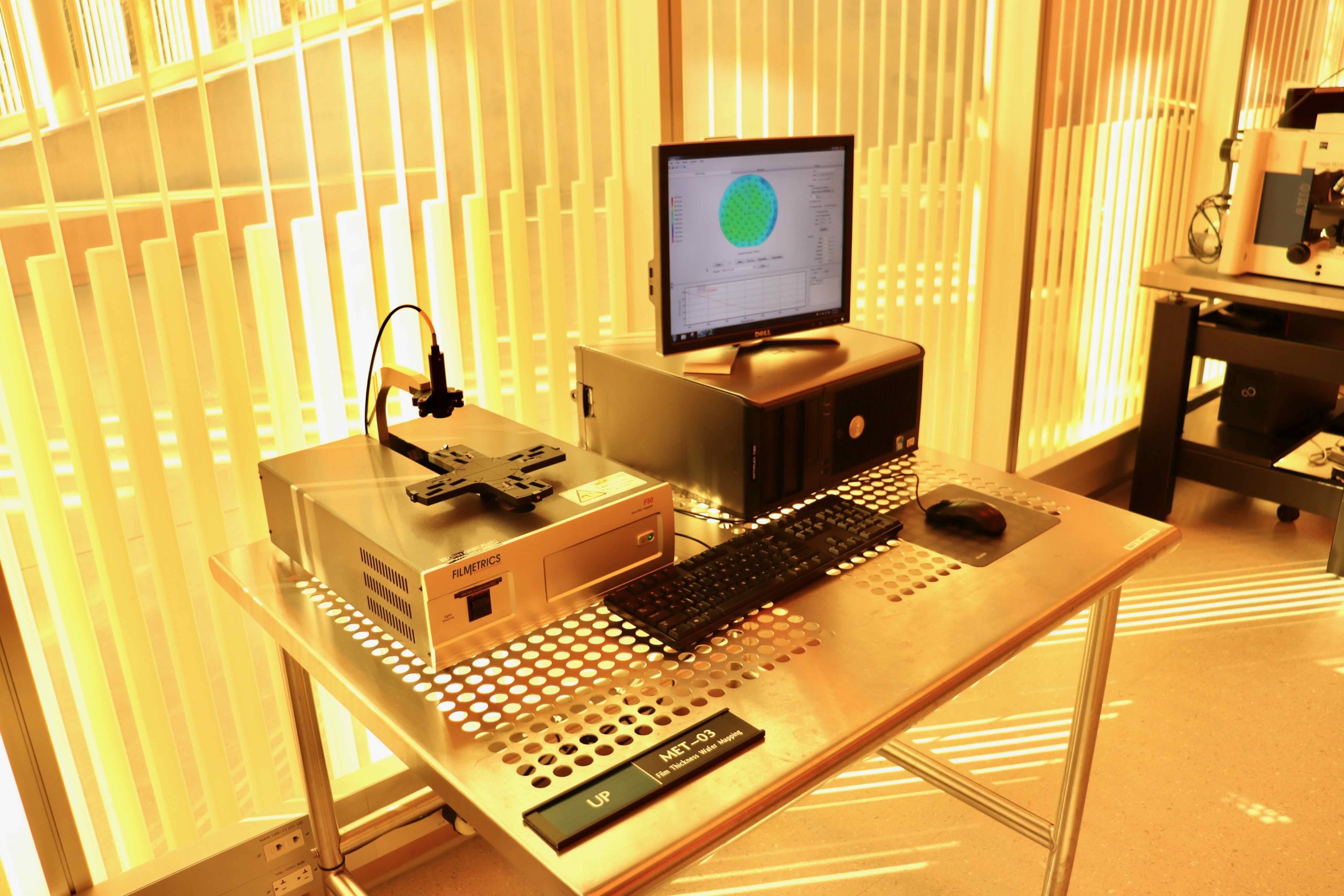

Filmetrics F50 Reflectometer – UV Filter

TOOL ID: MET-03

The Filmetrics F50 family of products can map film thickness as quickly as two points per second. A motorized R-Theta stage accepts standard and custom chucks for samples up to 200mm in diameter. This system has a UV filter installed and is used for measuring film thicknesses of UV sensitive photoresists. A second F50 system without UV filters is located in the QNF (MET-11).

Map patterns can be polar, rectangular, or linear, or you can create your own with no limit on the number of measurement points. Dozens of pre-defined map patterns are supplied.Go to Page

Filmetrics F50 Reflectometer

TOOL ID: MET-11

The Filmetrics F50 family of products can map film thickness as quickly as two points per second. A motorized R-Theta stage accepts standard and custom chucks for samples up to 200mm in diameter.

Map patterns can be polar, rectangular, or linear, or you can create your own with no limit on the number of measurement points. Dozens of pre-defined map patterns are supplied.Go to Page

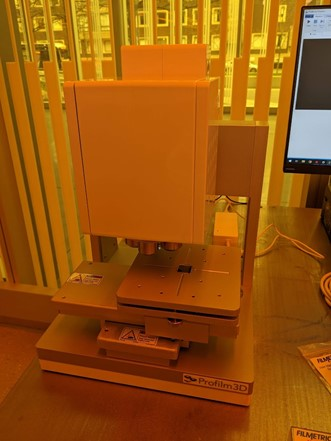

Filmetrics Profilm3D Optical Profilometer

Filmetrics Profilm3D Optical Profilometer

Tool ID: MET-05

The Profilm3D is an optical profilometer capable of white light interferometry (WLI), green light interferometry (GLI), and phase shift interferometry (PSI). It can measure surface topography, roughness, and step heights from 1 nm up to 10 mm. The tool has two Mirau interferometry objectives: a 10x objective with a field of view ~2x2mm for high speed and large area measurements and a 50x objective for spatial resolution up to 0.176 μm.

Applications

- Step height measurements

- Surface roughness measurements

- 3D mapping of surfaces

J.A. Woollam V VASE Spectroscopic Ellipsometer

TOOL ID: MET-06

The VASE is one of the most accurate and versatile ellipsometer for research on all types of materials: semiconductors, dielectrics, polymers, metals, multi-layers, and more.

It combines high accuracy and precision with a wide spectral range up to 300 to 1100nm. Variable wavelength and angle of incidence allow flexible measurement capabilities including:

- Reflection and Transmission Ellipsometry

- Generalized Ellipsometry

- Reflectance (R) intensity

- Transmittance (T) intensity

- Cross-polarized R/T

- Depolarization

- Scatterometry

- Mueller-matrix

Jandel Multi Height Four Point Probe

TOOL ID: MET-08

- Allows probing of wafers, ingots, or samples of widely varying dimensions

- Locking mechanism allows the arm to be moved up and down the steel pole and locked to suit any sample height

- Plug attached to the arm prevents the wiring from getting entangled with samples, fingers etc

- Smooth base for positioning samples

- Includes one Jandel Cylindrical probe head

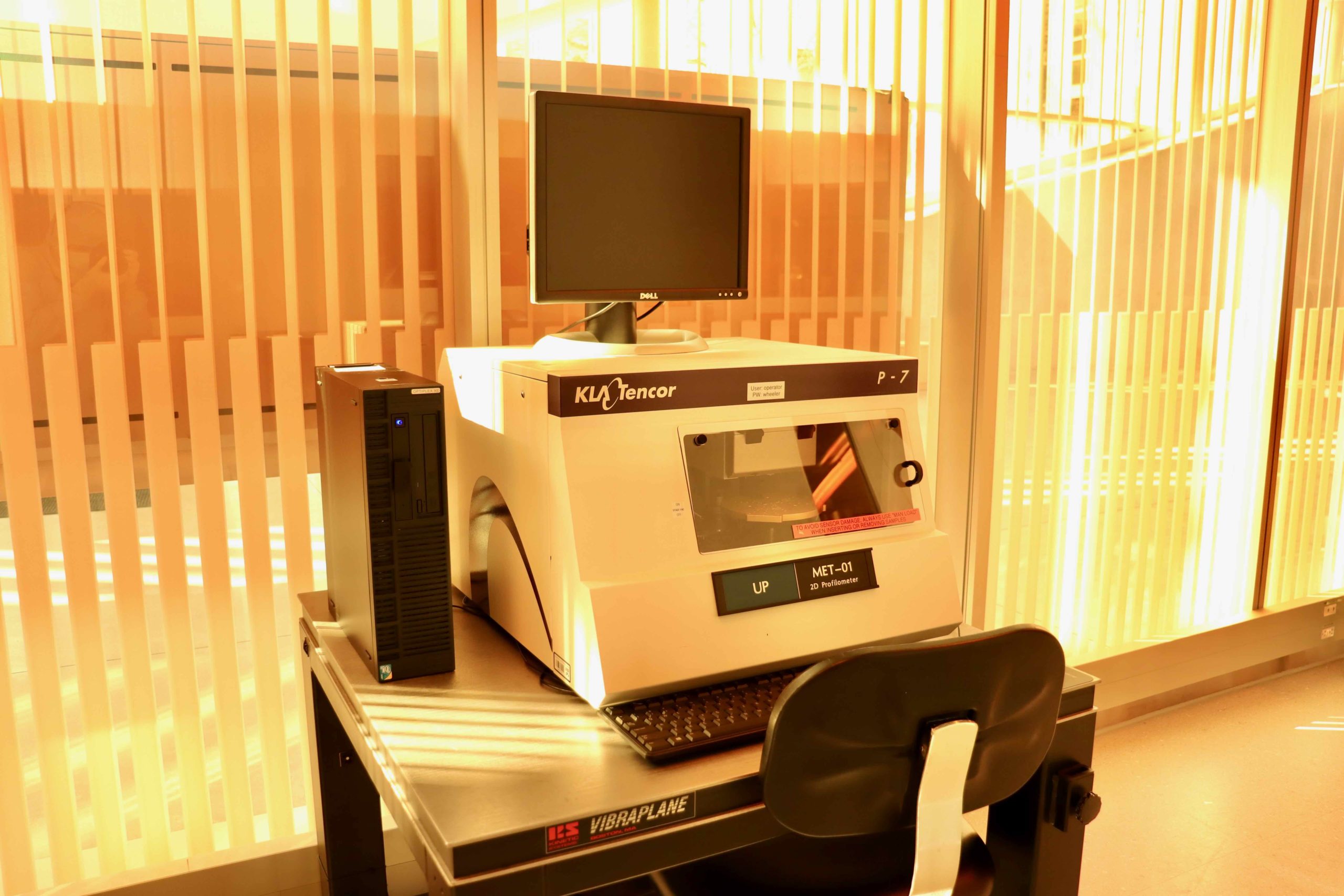

KLA Tencor P7 2D Profilometer – 1

TOOL ID: MET-01

The P-7 stylus profiler offers industry leading measurement repeatability for reliable measurement performance. The surface measurement system has 150 mm scan length standard – the only stylus profiler on the market to offer long scan capability without the need for stitching. The UltraLite® sensor includes dynamic force control, excellent linearity, and the highest vertical resolution making it the best sensor available on a surface measurement system. Finally, this stylus profiler’s surface measurement system includes point-and-click operation and the productivity package to offer the easiest to use tool on the market with the features required by university, R&D, and production environments.

The P-7 Stylus profiler is capable of addressing a wide range of surface measurements and applications:

- Thin film step height measurements

- Thick film step height measurements

- Photo resist / soft films

- Etched trench depth

KLA Tencor P7 2D&3D/stress profilometer

TOOL ID: MET-02

The P-7 stylus profiler offers industry leading measurement repeatability for reliable measurement performance. The surface measurement system has 150 mm scan length standard – the only stylus profiler on the market to offer long scan capability without the need for stitching. The UltraLite® sensor includes dynamic force control, excellent linearity, and the highest vertical resolution making it the best sensor available on a surface measurement system. Finally, this stylus profiler’s surface measurement system includes point-and-click operation and the productivity package to offer the easiest to use tool on the market with the features required by university, R&D, and production environments.

The P-7 Stylus profiler is capable of addressing a wide range of surface measurements and applications:

- Thin film step height measurements

- Thick film step height measurements

- Photoresist / soft films

- Etched trench depth

- Materials characterization for surface roughness and waviness

- Surface curvature and form

- 2D stress of thin films

- Dimensional analysis and surface texture

- 3D imaging of various surfaces

- Flatness or curvature

- Defect review and defect analysis

MET-02 has a stylus with an extra large height range (up to 1 mm), is capable of 3D scans, and is configured for stress measurements. MET-02 should be used for these applications, and MET-01 should be used for standard step height measurements.

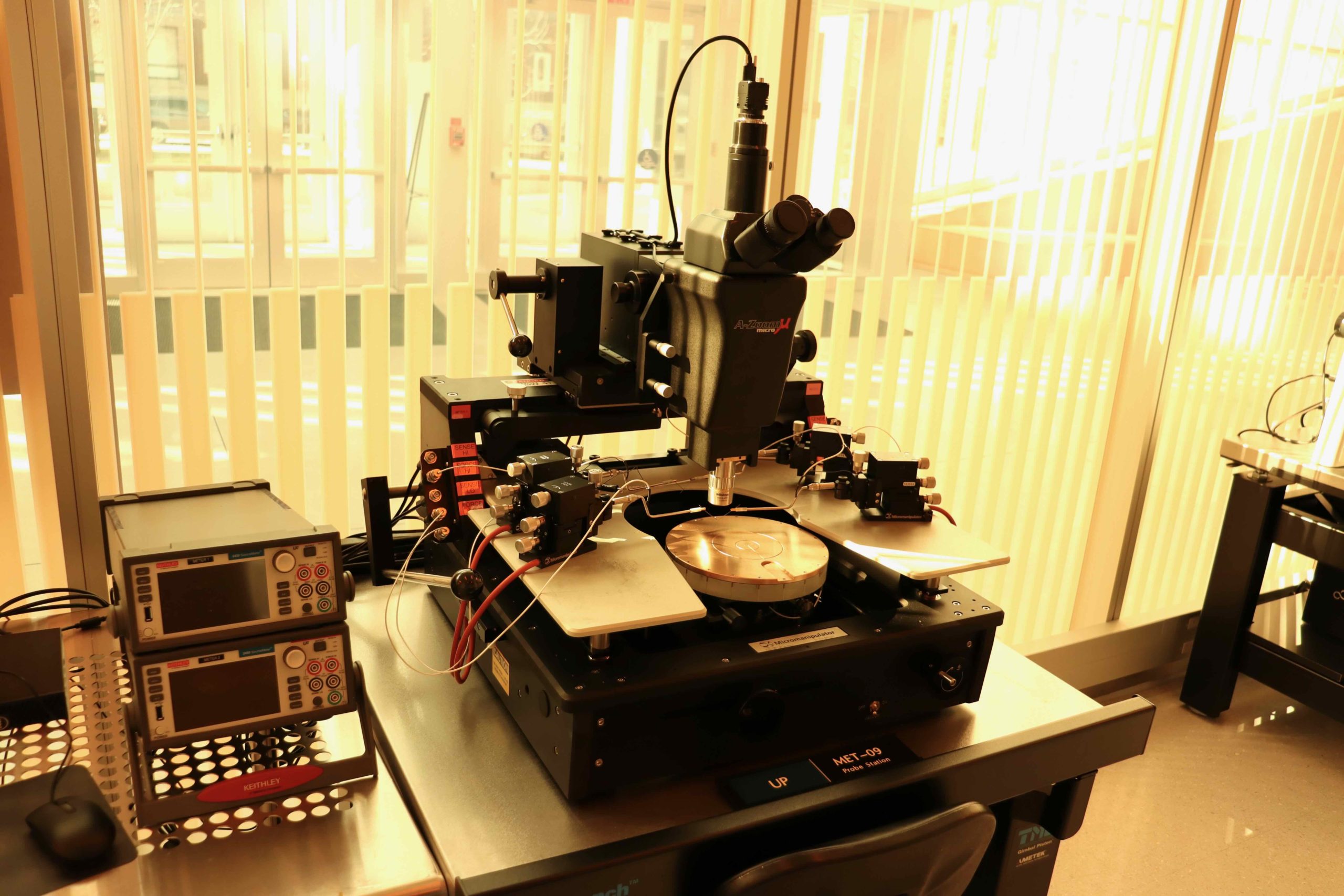

Micromanipulator 4060 Probe Station

TOOL ID: MET-09

The Micromanipulator Model 4060 probe station is a high efficiency general purpose 6 – 8” (150 – 200mm) manual analytical probe station. The 4060 is designed for ease of use in everyday failure analysis, device characterization, and reliability testing applications. The 4060 station combines the value of efficient use with the confidence of consistent, accurate electrical and mechanical performance. The system is configured with two Keithley 2450 Graphical SourceMeter (SMU) Instruments.

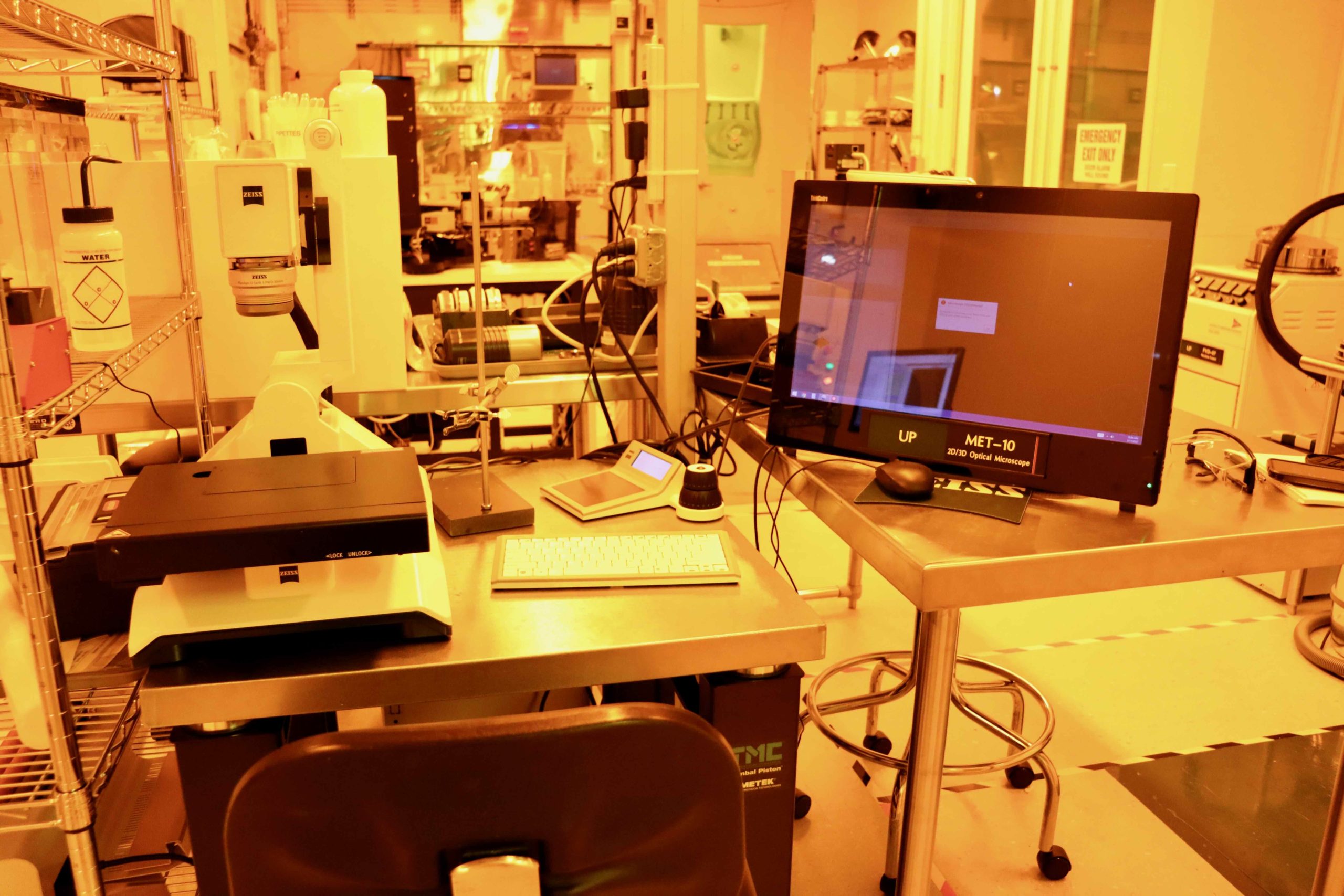

Zeiss Smartzoom5 2D/3D Optical Microscope

TOOL ID: MET-10

The Zeiss SmartZoom is an automated inspection microscope with multiple objectives, optical zoom, autofocus, multiple LED light sources, and tilt capability. Spatial calibration is automatically adjusted.Go to Page

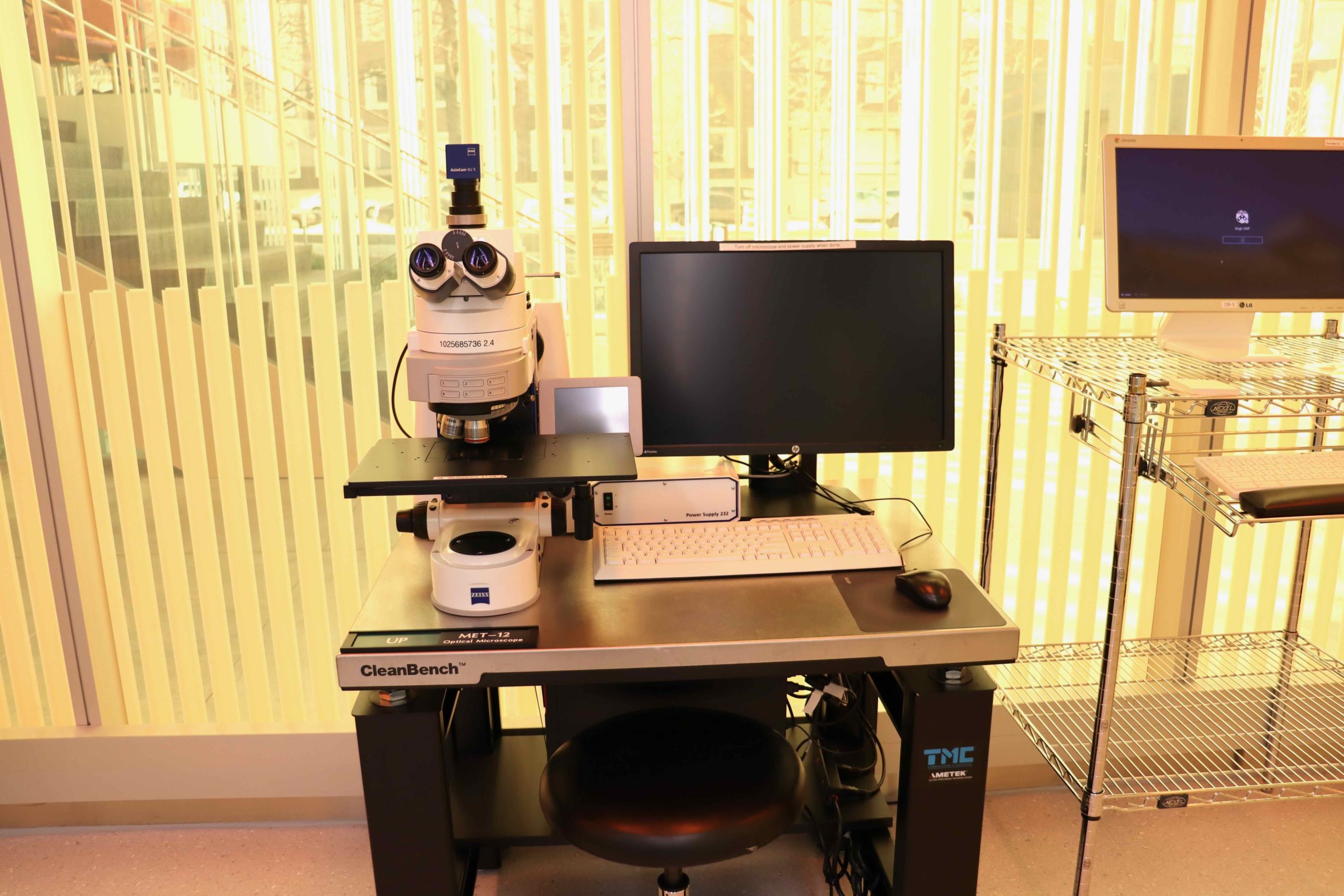

Zeiss Axio Imager M2m Microscope

TOOL ID: MET-12, 13, 14, 15

In Normal operation, it is possible to observe ~2 µm diameter objects in the reflected and transmitted mode. Furthermore, the following contrasting techniques are available: bright-field, dark-field, Circular Differential Interference Contrast (C-DIC) using circularly polarized light, polarization contrast, and polarization with additional retarder. The image snapped can be analyzed using the annotation tool on the software.

ADT 7100 Dicing Saw

TOOL ID: BE-04

LOCATION: Packaging Lab

Workhorse dicing saw with precision dicing and alignment system. This is an automated tool with a 2″, DC-brushless, 1.2 kW, Front-mounted, Air-bearing Spindle (60 krpm Max.), with closed-loop turntable, and is optimized for multi-angle dicing of thin, tight tolerance products up to 200 mm x 200 mm.

ADT Model 966 Workpiece Mounting Unit

ADT Model 966 Workpiece Mounting Unit

The ADT Workpiece Mounting Unit, used in conjunction with the dicing saw, enables mounting wafers to frames, using various kinds of tape. We have Ultron systems Part 1007R-11.5 “blue tape” we use for general purpose dicing. If you are cutting smaller pieces, we provide Ultron Systems Part 1020R-11.5 “UV release” tape. This gives a more adhesive film that can be released with direct UV light exposure.

CEE 200X Spinner

CEE 200X Spinner

TOOL ID: SPN-07

LOCATION: Packaging Lab

Spinner for coating substrates with resists and protective coverings for laser-cutting and dicing. Can also be used to apply PDMS. Control of ramp rate and speed. Includes wafer centering step.

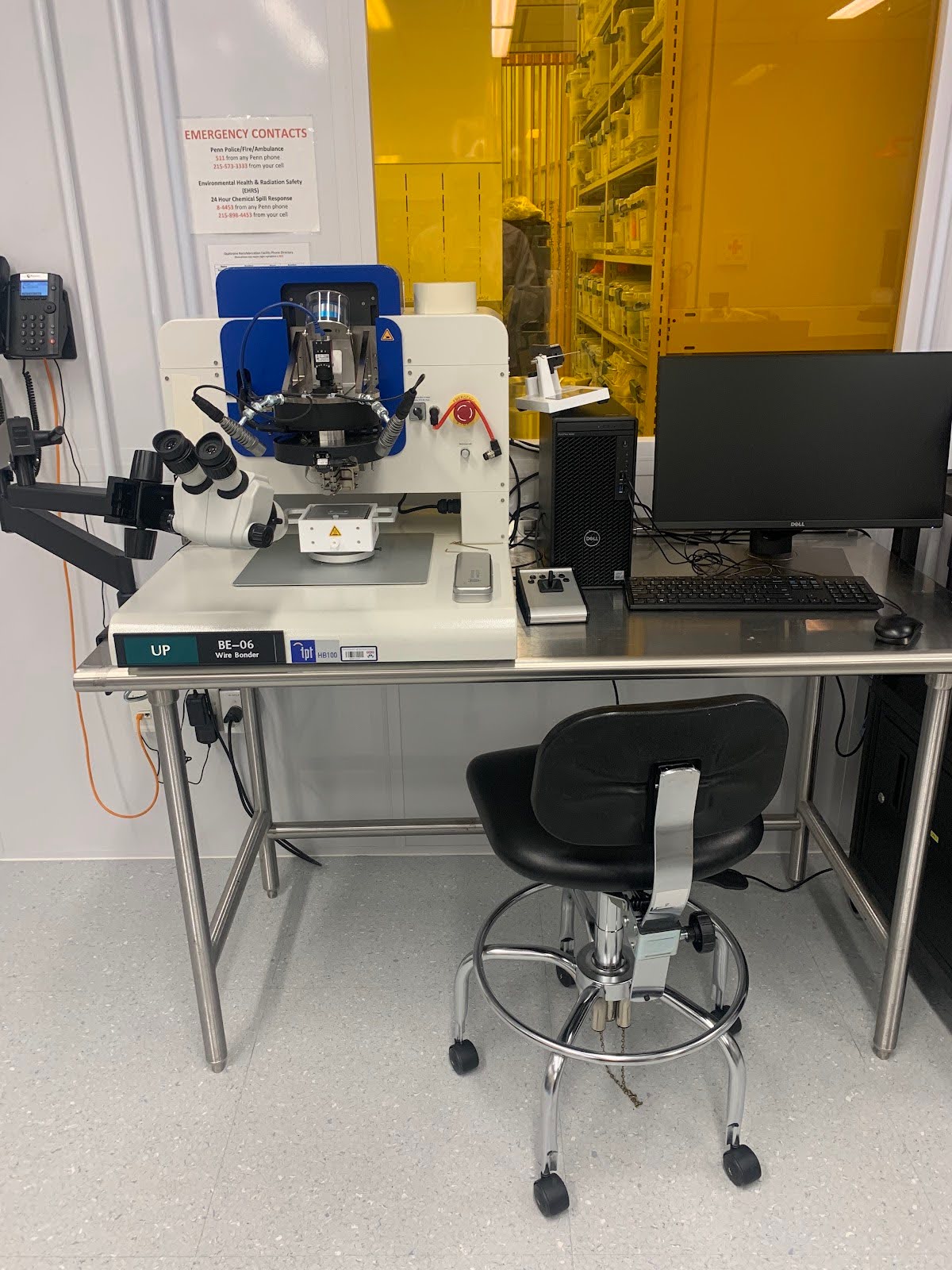

HB100 Wire Bonder

HB100 Wire Bonder

TOOL ID: BE-06

LOCATION: Packaging Lab

The HB100 is an ultrasonic wire bonder offering a high-precision X-Y-Z and Theta control. All parameters, such as bonding force, ultrasonic power, time & temperature are controlled digitally. The bonder offers reliable wire and ribbon handling through vertical feed and motorized clamp. The Model HB100 employs the ultrasonic bonding method that mainly depends on four variables to

connect two metals: force, ultrasonic energy, time, and heat. FORCE is introduced to promote the plastic flow (deformation) and intimate coupling between the bonding tool, the wire, and the substrate. ULTRASONIC (63 kHz, optional 100kHz) scrubbing displaces surface contaminants and enforces the

metal to metal coupling. TIME for the bonding process is set to sufficient duration to cause solid-state diffusion. HEAT is only used with gold wire. It eliminates surface contaminants, leading to stronger connections.

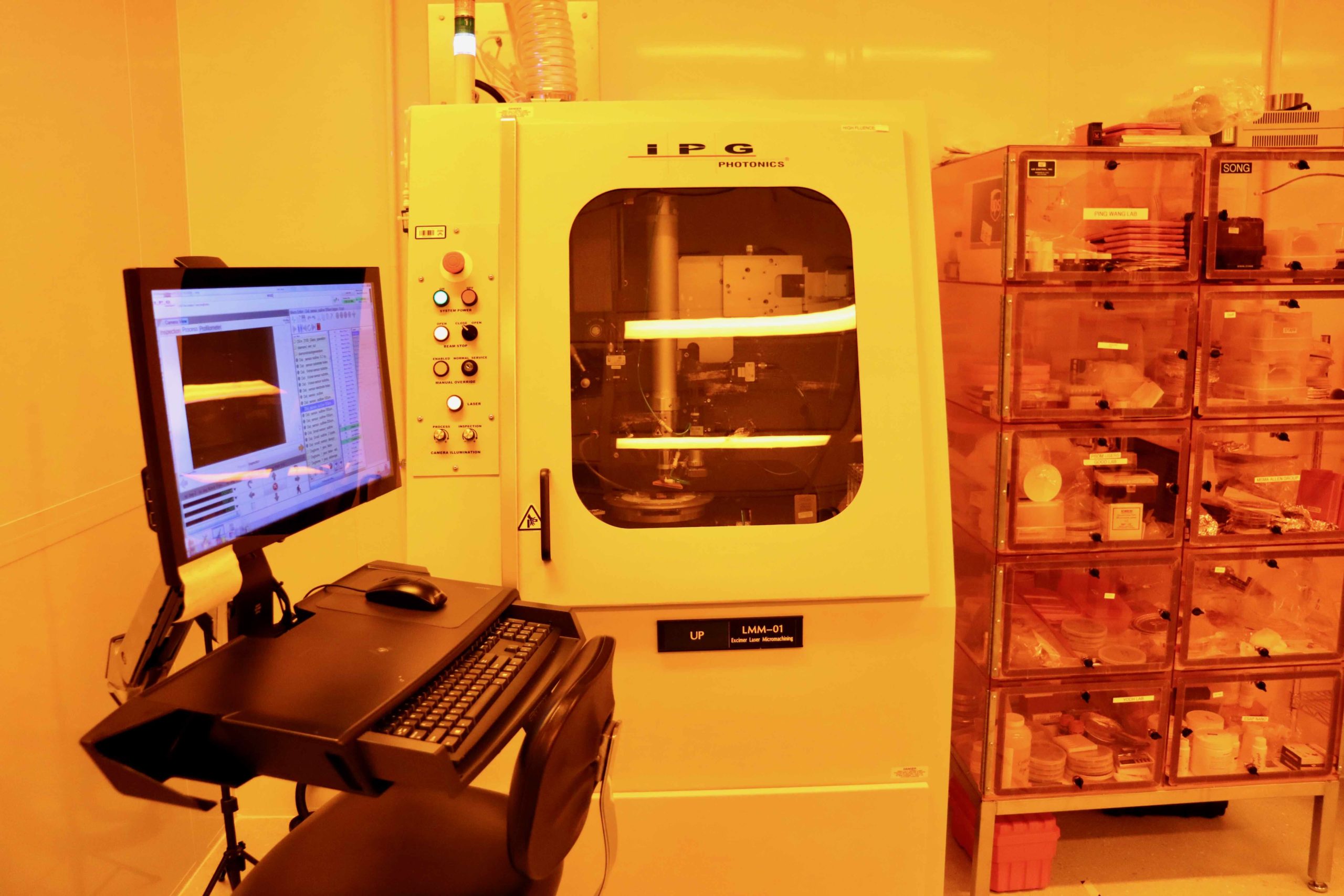

IPG Microsystems’ IX-255

IPG Microsystems’ IX-255

TOOL ID: LMM-01

LOCATION: Packaging Lab

The IPG IX-255 Excimer Laser is a highly flexible UV laser micromachining system for multi-purpose, R&D and production applications. The system combines a Class 1 workstation integrated with a proprietary UV (193nm) laser and beam shape selector (infinitely variable rectangular and discrete circular) to machine transparent samples such as plastic, glass, and PDMS.

Applications:

- Micro Drilling

- Annealing

- Thin-film Removal

- Laser Lift-off (LLO)

- Dicing

Features

- Pre-set Configurations for High Fluence and Large Field of View Applications

- Selectable Beam Shapes for Automated, Complex Micromachining

- Precision Stages with <3 μm Motion Control Accuracy

- Dual Magnification Vision System with Sub-micron Part Alignment

- 193 nm Laser

- Linear Mask Changer for Complex Features and Shapes

Accepts DWG and DXF CAD files

Kulicke & Soffa 4523 Wire Bonder

TOOL ID: BE-03

LOCATION: Packaging Lab

Aluminum and gold wire wedge bonder. It provides digital controls with semiautomatic bonding cycle, but manual alignment.

The bonder can be operated in auto cycle or manual mode. The auto cycle mode is the preferred mode for most applications. Stitch bonding can be performed in the auto cycle mode. The manual mode is useful when the elevation between subsequent bond-pairs is substantially different.

Applications:

Aluminum wedge wire bonding

Gold wedge wire bonding

SCS Labcoter 2 (PDS 2010) Parylene Deposition System

SCS Labcoter 2 (PDS 2010) Parylene Deposition System

TOOL ID: PVD-07

LOCATION: Packaging Lab

The SCS Labcoter 2 (PDS 2010) vacuum deposition system is specifically designed to bring Parylene technology to the laboratory. Its size and portability make it the ideal choice for universities and research institutions looking to develop and design with Parylene conformal coatings.

As a high quality, compact coating unit, the PDS 2010 is well suited for a range of applications, including circuit boards, sensors, wafers, medical devices and elastomeric components for research, development and repair.

Rapid Thermal Annealer-01

Rapid Thermal Annealer-01

TOOL ID: RTA-01/02

LOCATION: Bay 1

The RTA can anneal samples up to 1200° C. The processes can be run under atmospheric pressure under different gas environments. The tool can hold 4’’ wafers or smaller chips.

Only MOS-compatible materials are allowed. Compound semiconductors and metals are not allowed. The processes can be run in Oxygen, Nitrogen, Forming Gas, and Argon environments. Allowable anneal times are from 30 seconds to 15 minutes depending on the anneal temperature.

Sandvik LPCVD & Anneal Furnace

TOOL ID: CVD-02

The Sandvik LPCVD consists of 4 horizontal tubes:

Tube 1: Wet/Dry Silicon Oxide deposition.

Tube 2: Low Stress Silicon Nitride deposition.

Tube 3: Clean anneal.

Tube 4: General anneal.

The tool is configured for 100 mm (4″ wafers) and can process up to 50 wafers at a time.

Go to Page

HF Process Bench

-

- Substrates up to 150mm

- Cascade rinse tank

- Goose neck sink

- N2 and DI water guns

RCA Clean Bench

RCA Clean Bench

- Substrates up to 150mm

- Cascade rinse tanks

- Goose neck sink

- N2 and DI water guns

RENA Compass Dual Stack SRD

RENA Compass Dual Stack SRD

- Substrates up to 150mm

- Recipe driven

- Fully programmable (RPM, N2 and temp)

- Dedicated unit for RCA cleaned wafers

Tousimis Automegasamdri 931 Critical Point Dryer

Tousimis Automegasamdri 931 Critical Point Dryer

- Substrates up to 100mm

- Micro-filtered LCO2

- Slow-fill capability

IPG Photonics IX280-DXF Laser System

TOOL ID: LMM-02

The IX280-DXF is a highly flexible laser micro-machining system for multipurpose, R&D and production applications. The system combines a Class 1 workstation integrated with a fiber laser and all necessary software.

Cutting Applications

- Ceramics, Metals, Polymers and Semiconductor Materials

- Patterning of ITO and other Thin-films

Drilling Applications

- Hole Diameters down to 15 μm

Class 1 Micromachining Workstation

- Lasers at 532 or 1064 nm

- Pulse Energy up to 15 Joules (1064 nm)

- X-Y Positional Accuracy: <3 μm

- Z-theta Accuracy: <10 μm, ±0.02°

- Galvanometer Scanner or Fixed Optics

- Thermal Cutting Head

- Step and Scan Stage/ Galvo Integration

Vision System Resolution 0.12 μm/ pixel

DXF and CSV File Interface

IPG Microsystems’ IX-255

TOOL ID: LMM-01

The IPG IX-255 Excimer Laser is a highly flexible UV laser micromachining system for multi-purpose, R&D and production applications. The system combines a Class 1 workstation integrated with a proprietary UV (193nm) laser and beam shape selector (infinitely variable rectangular and discrete circular) to machine transparent samples such as plastic, glass, and PDMS.

Applications

- Micro Drilling

- Annealing

- Thin-film Removal

- Laser Lift-off (LLO)

- Dicing

Features

- Pre-set Configurations for High Fluence and Large Field of View Applications

- Selectable Beam Shapes for Automated, Complex Micromachining

- Precision Stages with <3 μm Motion Control Accuracy

- Dual Magnification Vision System with Sub-micron Part Alignment

- 193 nm Laser

- Linear Mask Changer for Complex Features and Shapes

Nanoscale Characterization

JEOL 7500F HRSEM

The JEOL 7500F Scanning Electron Microscope provides ultrahigh resolution of 0.8 nm at 30 kV and 1 nm at 1 kV, which is particularly useful for soft-matter studies. The JEOL 7500F SEM is our dedicated conventional and high-resolution imaging microscope. It is equipped with multiple detectors and imaging modes that allow for the study of a wide range of solid materials. Secondary and backscattered electron detectors allow for imaging of sample surfaces, whereas a scanning-transmission electron detector shows the internal structure of materials. Through a stage biasing system, referred to as the “gentle-beam” mode, the electron beam interacting with the sample may be reduced to a fraction of the accelerating voltage of the gun, allowing for the imaging of soft or insulating samples without the need for carbon or metal coating. An EDAX Energy Dispersive x-ray spectrometer (EDS) is available for chemical characterization via spectra or element maps.Go to Page

Quanta 600 FEG ESEM

An FEI Quanta 600 FEG Mark II Environmental Scanning Electron Microscope achieves 1.5 nm resolution in ESEM mode and can be operated under a range of gaseous environments from 6 x 10-4 Pa to ~1000 Pa. It is equipped with a special wet STEM detector that is ideal for the imaging of nanoparticles in biological systems. This system is our platform for in-situ electron microscopy development with heating and cooling stages allowing imaging from 20-1000°C, dual Kleindiek nano-manipulators with a micro-droplet injection system for electrical and mechanical measurements, and gas injection systems for platinum and gold e-beam deposition. The Quanta SEM is equipped with a unique array of accessories to enable the combination of high-resolution imaging and nanoscale manipulation allowing for powerful in-situ experiments involving controlled stimuli and correlated response. An EDAX Energy Dispersive x-ray spectrometer (EDS) allows for chemical characterization via spectra, element mapping, or phase mapping, and an electron backscatter diffraction detector (EBSD) is available for characterization of crystallographic structures. In-situ capabilities include: nanoscale manipulation of specimen or probe, access to the large sample volume by fluids, gases, electrical, optical and mechanical probes; detection of sample response to such probes, including the electron beam itself; and the temperature dependences of all these phenomena.Go to Page

TESCAN S8000X FIB/SEM

The TESCAN S8000X is a versatile instrument for the characterization of materials. It combines a plasma-source focused ion beam microscope and a high- resolution (BrightBeam) scanning electron microscope. The FIB microscope is equipped with a Xe+ ion plasma source and will include additional gases in the near future. The Xe plasma can generate a focused beam up to 1 uA, which allows very high milling rates (up to 50X faster than the prior Ga+ ion technology) and does not lead to deleterious ion implantation in the same way that Ga+ ions do. The BrightBeam SEM is a field-free, ultra-high resolution electron microscope whose optics allow improved resolution, even at low energies. This improves imaging of non-conducting samples. The instrument is equipped with advanced analytical capabilities, as well. These include a Time-of-Flight Secondary Ion Mass Spectrometery (ToF-SIMS) that can detect the ions emitted from the sample, allowing chemical characterization. ToF-SIMS is especially useful in detecting light elements, including the discrimination of hydrogen and deuterium. An Energy Dispersive x-ray spectrometer (EDS) allows for additional, complementary chemical characterization. The S8000X is also equipped with a cryogenic stage and a sample transfer loadlock, allowing work down to -160 C or introduction of frozen samples into the tool to be milled. A cryogenic Kleindiek nanomanipulator enables users to interact with the sample in-situ as well as lift-out frozen sections for subsequent TEM analysis.

This instrument was purchased with support from a National Science Foundations’ Major Research Instrumentation grant (NSF MRI #1828545). Additional support from the Laboratory for Research on the Structure of Matter (University of Pennsylvania Materials Research Science and Engineering Center (MRSEC) (DMR-1720530).Go to Page

The JEOL NEOARM is a scanning / transmission electron microscope, equipped with a spherical aberration corrector for the probe-forming optics. This corrector has improved stability and optimizes 5th order aberrations, leading to an as-installed resolution of <0.63Å at 200kV, and a <1.92Å at 30kV. The instrument is a high-brightness cold field emission instrument. It is equipped with two large area energy dispersive x-ray spectrometers that permit rapid atomic-resolution EDS mapping. It is equipped with a Gatan Image Filter, incorporating DualEELS capability to ensure accurate energy calibration and a K2-IS direct electron detector at the end of the filter. This detector has a detection quantum efficiency that is close to 1.0, and thus allows high sensitivity, leading to the detection of very high energy losses. The detector also allows 2k x 2k image acquisitions at 400 frames/second, and 512k x 2k image acquisitions at 1600 frames/second, making it optimal for in-situ/operando microscopy. This JEOL NEOARM was the first to be installed in the U.S.

For more information: https://www.

The JEOL F200 is a 200kV scanning / transmission electron microscope with a cold field emission source, two large area energy dispersive x-ray spectrometers, and Gatan OneView IS camera for in situ/operando imaging at 30 frames per second. It incorporates STEMx capability.

For more information: https://www.

The ThermoFisher Krios is a dedicated cryo-EM, with an autoloader for high through-put sample observation and a Gatan BioQuantum electron energy loss spectrometer equipped with a K2 Summit direct electron detector. The cryo-EM is installed in a facility constructed to ensure an ultra-low humidity space for both the instrument and the associated sample preparation areas. The cryogenic sample preparation laboratories include facilities for cryo-plunge sample preparation, high-pressure freezing, and cryo-ultramicrotomy.

For more information: https://www.fei.

Scanning and Local Probe

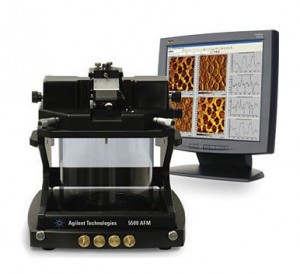

Agilent AFM

Modes

- Contact, tapping, lateral force, force spectroscopy, scanning Kelvin probe, MAC and Top MAC

Environmental control

- Ambient, purged gas, fluid environments with heated and cooled stages

Applications: Controlled-environment AFM (fluid, purged gas, temperature- programmed). Polymers, electrochemistry, force spectroscopy. Magnetically-excited AFM.

Scan range

- 90μm × 90 μm × 7 μm closed-loop scanner

- 9 μm × 9 μm × 2 μm open loop scanner

Noise floor

- <5 Å (large scanner)

- <1 Å (small scanner)

Controller

- Ten 16-bit channels input

- Four 24-bit channels out

Go to Page

Asylum AFM

Modes available

- Contact, AC (tapping) and Dual AC, 1-D forces, lateral force, nanolithography, Electrostatic Force, Kelvin probe, conductive AFM, Magnetic Force, piezoelectric force, thermal AFM

Applications

- Stiffness and adhesion measurements, frictional force imaging. Nanolithography, electrostatic force microscopy, and scanning surface potential. Conductive AFM, magnetic and piezoresponse force microscopy.

Scan range

- 90μm × 90μm × 15μm closed loop

Z noise

- <0.06nm 0.1Hz-1kHz BW

Cantilever noise

- <0.02nm Adev, 0.1Hz-1kHz BW.

Analog to Digital Converters

- One 16-bit, 5 MHz channel

Digital to Analog Converters

- Five 16-bit 100kHz channel

Direct Digital Synthesizer

- Six 24-bit 100kHz channels, plus two 10-bit 10MHz summed on a single DAC

Bruker Icon AFM

AFM modes

- PeakForce (with quantitative nanomechanics), tapping, contact, lateral force, magnetic force spectroscopy, Kelvin probe, conductive AFM, tunneling AFM, electrostatic force, magnetic force, piezoelectric force, torsional resonance mode.

Applications: Nano-mechanics, whole-wafer inspection, scanning conductivity/resistance microscopy. Thermal AFM. Electrical measurements of soft materials. Fluid tipholder.

X-Y scan range

- 90μm × 90 μm × 10 μm

Vertical noise floor

- <30 pm RMS

Current sensitivity

- pA to μA

Motorized position stage (X-Y axis)

- 180mm × 150mm

- 210mm vacuum chuck

Capabilities:

- Raman spectroscopy and photoluminescence in transmission and reflection modes. Scanning sample stage for mapping of optical properties

- Side-illumination for integrated contact and tapping AFM, scanning surface potential, and tip-enhanced Raman spectroscopy.

- Cryogenic vacuum sample holder with electrical feedthroughs.

- 405 nm, 600nm, and 785nm laser sources

- 600/mm and 1800/mm diffraction gratings

Applications:

- Graphene and 2D materials, polymers and monomers, inorganics and metal oxides, ceramics, coatings and thin films, photovoltaics, catalysts.

- Active pharmaceutical ingredients and excipients mapping and characterization, polymorph identification, phase determination.

- Disease diagnosis, dermatology, cell screening, cosmetics, microbiology, protein investigations, and drug interactions.

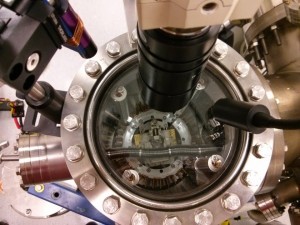

HV STM

Omicron STM-1 scanner

- 2 μm x-y range

- 20-50 pA min current

RHK SPM 1000 controller

- 10 channel input

- 26-bit resolution

- complete signal access

Vacuum capability

- 10-8 mtorr

Accessories

- LEED, sample annealing, lock-in amplifiers, optical excitation

Applications: Atomically resolved imaging, density of states/bandgap analysis, photon-stimulated electrical properties, and nano-gap electrodes

Go to Page

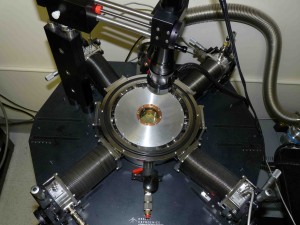

Probe Station

Probe arms

- 4 × 0-1GHz

- 2 × 1-20 GHz

Vacuum

- 10-6 torr

Lockin amplifiers

- SRS 830, SRS 844

Impedance analyzer

- Agilent E5061B 5Hz-3GHz

Network analyzer

- Agilent N5230C 10MHz-20GHz

Temperature Range

- LHe-100 °C

Electrometer

- Kiethley 6517A

Function generators

- SRS DS345 30MHz

Programming interface

- Labview

Applications: Conductance, resistance, impedance, capacitance measurements of circuits, devices, and resonators.

Go to Page

Raman-NSOM

AFM scanners

- 1μm, 10μm, and 100μm x-y range, 7μm z-range

- 491, 532, and 660 nm laser sources

Optical heads

- 0.7 NA 100× upright air lens

- 1.3 NA 100× inverted oil immersion lens

Confocal Raman

- Adjustable pinhole size and objective lens alignment

Spectrometer

- 1800, 600, and 150/mm gratings and 75/mm Echele. Cooled CCD/EMCCD detector.

AFM modes

- Contact, tapping, force mapping, Kelvin probe, conductive AFM, lateral force. Tuning fork AFM allows custom-cut and etched metal probes.

Environmental control

- Enclosures for each scanner for gas purge. Heated sample stage, fluid cell.

Simultaneous AFM/Raman

- Keeps samples of varying topography in focus

Near Field Scanning Optical Microscopy (NSOM)

- AFM-aperture optical microscopy is available in transmission mode

Applications: Simultaneous chemical and topographic/mechanical analysis. In situ temperature measurement. AFM-aperture optical microscopy. Optical devices such as semiconductor lasers, waveguides, and plasmonic devices Investigation of cellular tissue, DNA, viruses and other biological objects. Nanotubes, nanowires, and quantum dots.

Go to Page

TIRF

Modes available

- Contact, AC (tapping) and dual AC, 1-D forces, lateral force, nanolithography, electrostatic force, Kelvin probe, conductive AFM, magnetic force, piezoelectric force, thermal AFM

Applications: Mechanics of cells, tissues, and polymers. Tagging and identification of cells, proteins, and molecules. Controlled dosing of samples via micropipette. Controlled environment (fluid, temperature) experiments.

Scan range

- 90μm × 90μm × 15 μm closed loop

Z noise

- <0.06nm 0.1Hz-1kHz BW

Cantilever noise

- <0.02nm Adev, 0.1Hz-1kHz BW

Accessories

- Micromanipulator, nano-injector

- Temperature-controlled chamber

- Environmental fluid cell

Bio prep-space

- CO2 incubator, Bio-safety cabinet

Optics

- 641, 532, 488 nm lasers

- Cascade II EMCCD camera with dual view filter

- Nikon inverted optical microscope

- 10×, 20×, 40×, 100× objectives

Go to Page

UHV VT AFM

Scan range

- 10 μm x 10 μm x 1.5 μm

Z – resolution 0.01 nm

- 01 nm

Tunneling current:

- < 1pA – 330 nA

Gap voltage

- ± 5 mV to ± 10 V; applied to tip/cantilever, sample grounded

Vacuum achievable:

- 10-11 mbar or better

Sample size

- 3mm x 9mm 7mm diameter

Temp range

- 100K – 1500 K

Imaging modes

- Contact, tapping, and FM noncontact

Accessories

- LEED, Auger electron spectroscopy

- Evaporator, leak valves for controlled gas environment, sputter gun

Controller

- 20-bit, <25μV noise @ 60kHz up to 24 data acquisition signals

Applications: Atomically-resolved imaging of surfaces. Surface reconstruction. Friction and adhesion measurements. Surface potential and conductive AFM. Scanning Gate Microscopy. Scanning Kelvin Probe + Local dielectric AFM.

Go to PageProperty Measurement Group

This is the first of two PPMS systems in the facility. It provides magnetic field up to 9 T and temperatures from 1.7 K to 400 K. Users are able to perform DC magnetic moment, AC magnetic susceptibility, 2- and 4-wire magnetoresistance, photoconductivity, and Hall effect.

This system benefits from the PPMS EverCool-II™ dewar, which is the second generation of low-loss dewars with integrated Helium liquefier for the PPMS system from Quantum Design. It allows the continuous operation of the PPMS System without the supply with liquid Helium. The system is cryogen free for the user, and can hold temperatures below 2 K indefinitely.

Go to Page

This is second of two PPMS systems in the facility. It provides magnetic field up to 9 T and temperatures from 1.7 K to 400 K. Users are able to perform 2- and 4-wire magnetoresistance, thermal conductivity, heat capacity, Seebeck coefficient, and Hall effect measurements. The system is equipped with a turbo pump for the sample chamber.

Go to PageQuantum Design’s MPMS-XL provides sensitive SQUID (Superconducting QUantum Interference Device) magnetometry capabilities using Quantum Design’s Reciprocating Sample Option (RSO). In practice, we observe a noise floor of <10-8 emu for DC moment measurements. The system provides magnetic fields up to 7 Tesla and temperatures nominally between 2 K and 400 K. The MPMS has a fiber insert that permits studies of optically pumped magnetization, and an oven option that allows measurements up to 800 K when special needs arise.

MPMS XL Features

- Cryogen Free with EverCool®

- SQUID Sensitivity

- Multiple Measurement Modes

(Including Traditional MPMS DC Scan)

- Temperature Range: 1.8 – 400K

- 7 Tesla Magnet

Go to Page

The TriVista system is a triple spectrometer that has multiple input and detection ports that we can configure to provide Raman scattering down to 5 cm-1, photoluminescence excitation/emission spectral mapping, absorption, as well as spatial imaging of Raman scattering or photoluminescence with an infinitely tunable (in width and center wavelength) bandpass filter from 350 nm to 1000 nm. For Raman scattering, the system can operate in either additive mode for high resolution experiments or in subtractive mode for extreme stray light rejection. The system has both Si and InGaAs detectors, providing detection bandwidth from 350 nm to 1.7 microns. Light sources include a Xenon lamp (from which any spectral range can be selected without altering the illumination profile) and a laser at 532 nm. We are able to measure samples on solid substrates and liquids within cuvettes.

Instrumentation

- Princeton Instruments Tri-Vista 555 spectrometer (9 gratings)

- Princeton Instruments PIXIS-256E Si 2D array detector

- Princeton Instruments OMA-V InGaAs linear array detector

- Custom Optical Systems for Absorbance, Photoluminescence and Raman Scattering.